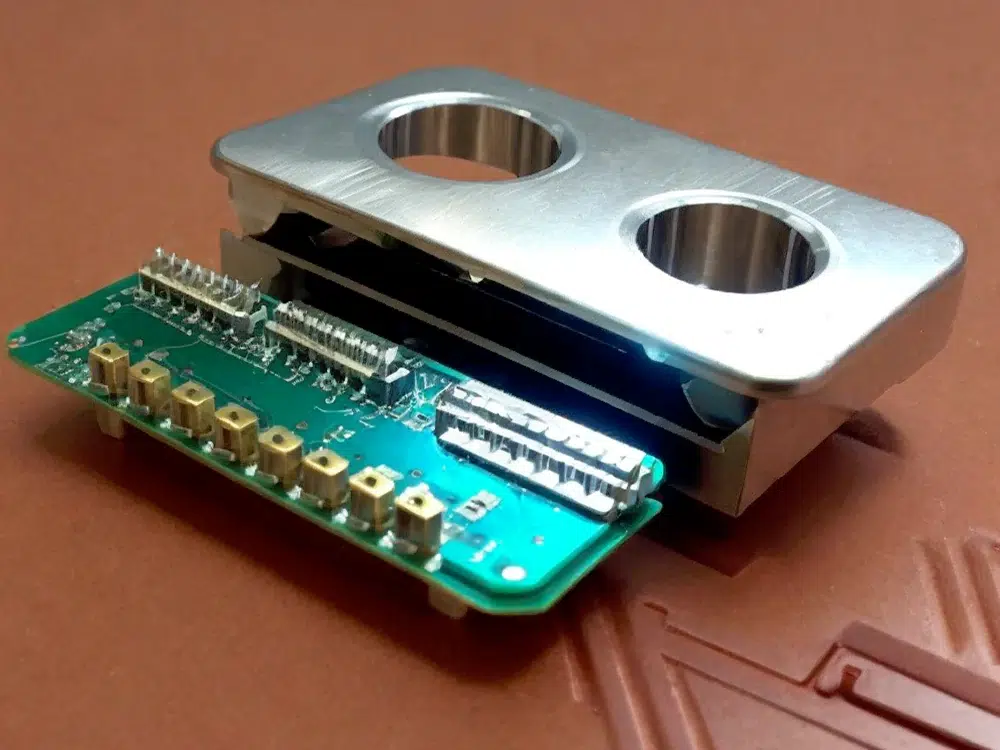

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the interconnection of various electronic components to create functional devices. Soldering is a fundamental process in PCB assembly, crucial for establishing reliable electrical connections between components and the PCB itself. However, soldering errors, such as solder bridge, can jeopardize the functionality and reliability of the circuit. In this article, we delve into the intricacies of solder bridge, exploring its causes, effects, prevention techniques, and corrective measures.

What is a soldering bridge?

A solder bridge occurs when solder unintentionally connects two adjacent electrical pads or pins that should remain isolated. This unintended connection can cause electrical shorts, leading to malfunctioning circuits or even permanent damage if not addressed promptly.

What causes solder bridging?

Several factors contribute to the formation of solder bridge:

• Excess Solder: Applying more solder than necessary increases the likelihood of solder flowing between closely spaced pads or pins.

• Incorrect Soldering Technique: Poor soldering technique, such as holding the soldering iron too long or at the wrong angle, can cause solder to spread uncontrollably.

• Inadequate Flux Application: Flux is essential for controlling solder flow and preventing bridges. Insufficient or improper application of flux can lead to solder bridges.

• Component Placement: Improper spacing or alignment of components on the PCB can create narrow gaps where solder can inadvertently flow, causing bridges.

• Temperature and Heat Management: Incorrect soldering iron temperature or uneven heat distribution can affect solder flow, potentially causing bridges if not managed properly.

What are the effects of Solder Bridge?

The consequences of solder bridge can range from minor issues to severe circuit failures:

Electrical Shorts: Solder bridges directly create unintended electrical paths between components or traces, leading to short circuits.

Malfunctioning Circuits: Shorts caused by solder bridges can disrupt the intended flow of current through the circuit, resulting in erratic behavior or complete non-functionality of the device.

Component Damage: Prolonged electrical shorts due to solder bridges can damage or degrade electronic components, reducing their lifespan or rendering them permanently non-functional.

How do you avoid solder bridges?

Preventing solder bridges requires attention to detail and meticulous handling of the soldering process:

Use Flux: Flux helps control the flow of solder and prevents it from spreading beyond intended areas. Apply flux to the solder joints before soldering.

Controlled Amount of Solder: Use just enough solder to form a reliable joint. Avoid excess, as it increases the risk of bridges.

Proper Heat Control: Ensure your soldering iron is set to the appropriate temperature for the solder and the components being soldered. Too much heat can cause solder to flow indiscriminately.

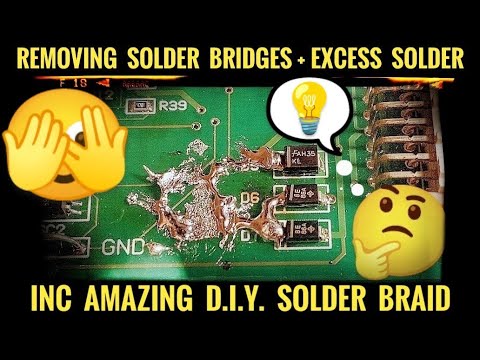

Solder Wick or Vacuum: In case a bridge forms, use desoldering wick (solder braid) or a desoldering vacuum pump to remove excess solder and correct the bridge.

Inspect Carefully: After soldering, inspect each joint carefully using magnification if necessary. Look for shiny, concave solder joints without any unintended connections.

How to correct a solder bridge?

Despite best efforts, solder bridges can occasionally occur. Here’s how to correct them effectively:

Desoldering Braid: Place the desoldering braid over the bridge and gently press the heated soldering iron on top. The braid will wick away the excess solder.

Desoldering Pump: Alternatively, use a desoldering pump (solder sucker) to suck up the excess solder from the bridge.

Inspect and Test: After removing the bridge, inspect the area again to ensure no residue solder remains. Test the circuit to confirm proper functionality.

Conclusion

Mastering soldering techniques, including preventing and correcting solder bridges, is crucial for anyone working with electronics. By understanding the causes of solder bridges and implementing proper techniques, you can significantly reduce the likelihood of errors and ensure the reliability of your solder joints.

A solder bridge occurs when solder unintentionally connects two adjacent electrical pads or pins that should remain isolated.

Several factors contribute to the formation of solder bridges:

Excess Solder

Incorrect Soldering Technique

Inadequate Flux Application

Component Placement

Temperature and Heat Management

The consequences of solder bridges can range from minor issues to severe circuit failures:

Electrical Shorts

Malfunctioning Circuits

Component Damage