As the demand for efficient energy storage solutions continues to grow, Battery Management Systems (BMS) have become critical components in various applications, from electric vehicles to renewable energy systems. At the heart of these systems lies the Battery Management Board (BMB), a key element that ensures the safe and efficient operation of battery packs. This article explores the functions, components, and importance of Battery Management Board in today’s energy landscape.

What is a Battery Management Board?

A Battery Management Board is an electronic circuit that manages and monitors the performance of battery cells within a battery pack. Its primary role is to ensure optimal performance, safety, and longevity of the batteries. The BMB acts as an intermediary between the battery pack and the device it powers, providing essential data and control functions.

What is the function of Battery Management Board ?

1. Cell Monitoring:

The BMB continuously monitors individual cell voltages, temperatures, and states of charge (SOC). This information is crucial for identifying any imbalances among the cells that could lead to reduced performance or safety hazards.

2. Balancing:

To maximize the lifespan and efficiency of the battery pack, the BMB performs cell balancing. This process equalizes the charge across all cells, preventing overcharging or deep discharging of individual cells, which can cause damage.

3. Protection:

Safety is paramount in battery management. The BMB includes protective features to prevent over-voltage, under-voltage, over-current, and over-temperature conditions. If any of these thresholds are exceeded, the BMB will disconnect the battery from the load or charger to prevent potential hazards.

4. Data Communication:

The BMB communicates vital information to external systems, such as the user interface or a vehicle’s control system. This data can include the state of charge, health status, and temperature of the battery pack, enabling users to make informed decisions about battery usage.

5. Charging Control:

The BMB manages the charging process to ensure that the battery is charged efficiently and safely. It regulates the charging current and voltage according to the battery chemistry and state of charge.

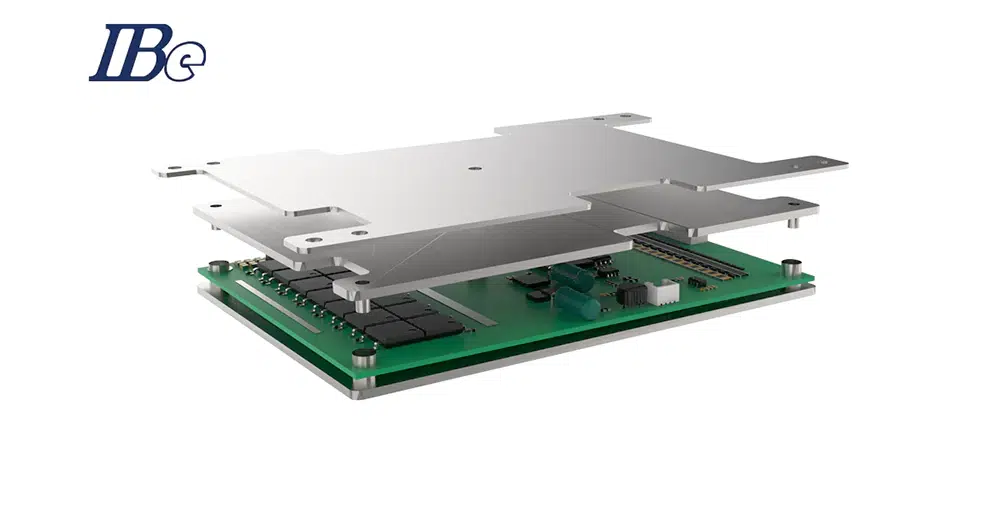

What are the components of Battery Management Board ?

A typical Battery Management Board consists of several key components:

– Microcontroller: The brain of the BMB, responsible for processing data from sensors and making real-time decisions based on the monitored parameters.

– Voltage and Temperature Sensors: These sensors continuously monitor the voltage of individual cells and the temperature of the battery pack to ensure safe operation.

– FETs (Field Effect Transistors): Used for controlling the charging and discharging of the battery cells, ensuring efficient energy flow.

– Balancing Circuits: These circuits help equalize the charge among cells to enhance performance and longevity.

– Communication Interfaces: Protocols such as CAN, I2C, or RS-485 allow the BMB to communicate with external devices, enabling real-time monitoring and control.

Why do we need Battery Management Board ?

1. Safety: The primary function of the BMB is to ensure the safety of battery operations. By preventing conditions that could lead to thermal runaway or battery failure, BMBs play a critical role in protecting users and equipment.

2. Efficiency: By optimizing the charging and discharging processes and ensuring balanced cell usage, BMBs enhance the overall efficiency of battery systems, leading to improved performance in applications like electric vehicles.

3. Longevity: Effective management of battery cells significantly extends the life of the battery pack. Proper balancing and temperature control prevent premature degradation, resulting in lower replacement costs and a smaller environmental footprint.

4. Adaptability: With the increasing complexity of modern energy systems, BMBs can be tailored to meet the specific needs of various applications, from consumer electronics to industrial energy storage.

What is the difference between a BMS and a battery protection board?

The terms Battery Management System (BMS) and Battery Protection Board (BPCB) are often used interchangeably, but they refer to different functions and complexities within battery management. a BMS is a more complex and feature-rich system that manages all aspects of battery performance, including protection, monitoring, and balancing. In contrast, a Battery Protection Board is focused solely on safeguarding the battery from unsafe conditions. The choice between the two depends on the specific requirements of the application and the level of management needed.

Battery Management System (BMS)

1. Comprehensive Management:

A BMS is a complete system designed to monitor and manage the entire battery pack. It oversees multiple functions including cell balancing, state of charge (SOC) calculation, and overall health monitoring.

2. Data Monitoring:

A BMS collects and processes data from various sensors (voltage, temperature, current) to provide detailed information about the battery’s performance and status.

3. Balancing:

A BMS typically includes cell balancing features to ensure that all cells within the battery pack charge and discharge evenly, which enhances battery life and performance.

4. Communication:

BMS systems often have communication interfaces (like CAN, I2C, or RS-485) to relay information to external systems, such as controllers or user interfaces, allowing for real-time monitoring and diagnostics.

5. Advanced Features:

BMS can incorporate advanced functionalities like predictive maintenance, fault diagnostics, and integration with other systems in electric vehicles or renewable energy applications.

Battery Protection Board (BPCB)

1. Limited Functionality:

A BPCB focuses primarily on protecting the battery from unsafe operating conditions. Its main purpose is to prevent over-voltage, under-voltage, over-current, and over-temperature situations.

2. Basic Monitoring:

While a BPCB may monitor some parameters (like cell voltage and temperature), it generally does not provide the comprehensive monitoring and balancing functions found in a BMS.

3. Simplified Design:

BPCBs tend to have a simpler design and are often less expensive than full BMS systems. They are suitable for applications where basic protection is sufficient.

4. Less Communication:

BPCBs typically do not include advanced communication capabilities, making them more limited in terms of data reporting and integration with other systems.

How do I choose a BMS board?

Choosing the right BMS board is crucial for ensuring the safety, efficiency, and longevity of your battery pack. Here are some key factors to consider when selecting a BMS:

1. Battery Chemistry

– Compatibility: Ensure the BMS is designed for the specific chemistry of your battery (e.g., Li-ion, LiPo, NiMH, lead-acid). Each type has different voltage and charging requirements.

2. Voltage and Capacity

– Voltage Rating: Match the BMS to the total voltage of your battery pack. BMS boards are available for different voltage ranges.

– Current Rating: Ensure the BMS can handle the maximum discharge and charge currents of your application. Check the continuous and peak current ratings.

3. Number of Cells

– Cell Configuration: Choose a BMS that supports the number of cells in series and parallel in your battery pack. Some BMS boards are designed for specific configurations (e.g., 4S, 8S).

4. Balancing Features

– Active vs. Passive Balancing: Determine whether you need active balancing (more efficient, allows for greater capacity) or passive balancing (simpler, typically sufficient for many applications).

5. Protection Features

– Over-voltage and Under-voltage Protection: Look for features that prevent cells from exceeding safe voltage limits.

– Over-current and Short Circuit Protection: Ensure the BMS can handle and mitigate excessive current draw.

– Temperature Protection: Check for temperature sensors and cutoff features to prevent overheating.

6. Communication Interface

– Data Reporting: Decide if you need a BMS that can communicate with external systems (like CAN, I2C, or UART) for real-time monitoring and diagnostics.

– User Interface Compatibility: Consider how the BMS integrates with user interfaces or controllers.

7. Size and Form Factor

– Physical Dimensions: Ensure the BMS fits within your battery pack’s space constraints.

– Mounting Options: Check for compatible mounting methods for your specific application.

8. Firmware and Configuration

– Programmability: Some BMS boards offer customizable settings for charge/discharge profiles, temperature thresholds, and balancing methods. Ensure it can be easily configured if needed.

9. Safety Certifications

– Compliance: Look for BMS boards that comply with relevant safety standards (e.g., UL, CE) to ensure reliability and safety in your application.

10. Reviews and Reputation

– Manufacturer Reputation: Research the manufacturer’s reputation in the industry. Reviews and user feedback can provide insight into the reliability and performance of their BMS products. IBE has been a professional BMS PCBA manufacturer since 2005.

Conclusion

Battery Management Boards are indispensable for the safe and efficient operation of battery systems in today’s energy-driven world. As technology continues to advance, the design and capabilities of BMBs will evolve, paving the way for even more efficient and reliable energy storage solutions. Investing in quality Battery Management Boards is essential for anyone looking to harness the full potential of battery technology, ensuring safety, efficiency, and longevity in their applications.

A Battery Management Board is an electronic circuit that manages and monitors the performance of battery cells within a battery pack. Its primary role is to ensure optimal performance, safety, and longevity of the batteries.

Cell Monitoring

Balancing

Protection

Data Communication

Charging Control

Microcontroller

Voltage and Temperature Sensors

FETs (Field Effect Transistors)

Balancing Circuits

Communication Interfaces