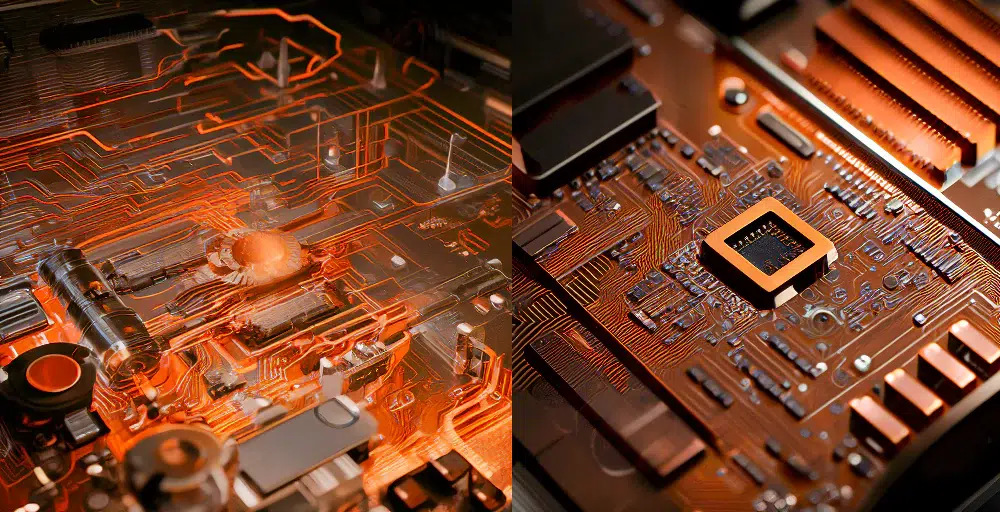

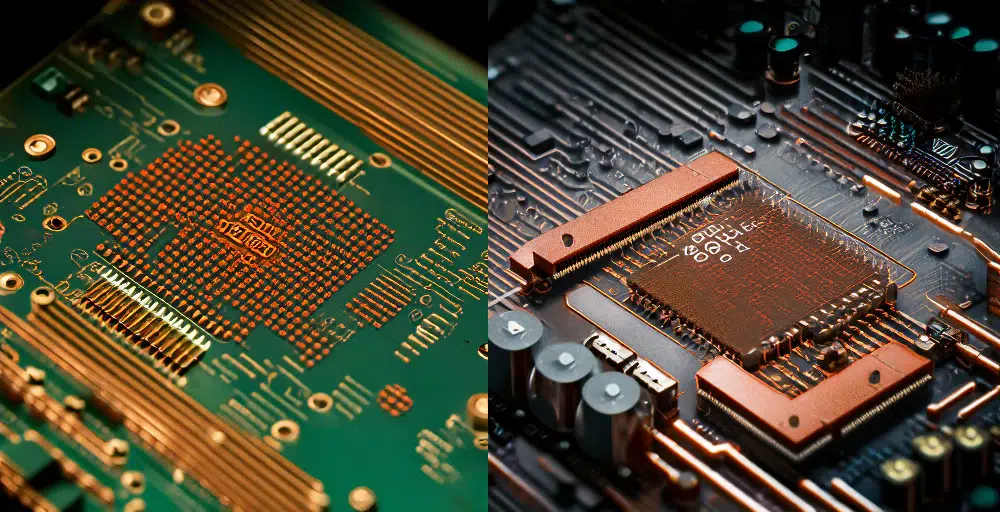

Copper pouring, also known as copper fill or copper flood, is a technique used in printed circuit board (PCB) design and manufacturing. It involves covering certain areas of the PCB with a continuous layer of copper, typically to achieve specific electrical or mechanical objectives.

The process of copper pouring begins with the PCB layout design phase. Designers use PCB design software to define areas on the board where copper should be poured. These areas are often referred to as copper pours or copper planes. During this step, designers specify the net or nets that the copper pour should be connected to, such as ground or power nets. Once the PCB layout is complete, the design software automatically fills in the defined areas with copper.

After all design components of a PCB are completed, there’s typically one final crucial step—copper pouring. Copper pouring involves covering the unused space on the PCB with copper, and various PCB design software offer intelligent copper pouring functions. Typically, areas where copper has been poured appear red, indicating that those areas are covered with copper.

Why is copper pouring necessary in PCB design?

Why is copper pouring necessary? Can’t we do without it? For PCBs, copper pouring serves several purposes, such as reducing ground impedance, improving immunity to interference, connecting to ground to reduce loop area, aiding in heat dissipation, and more.

1.Copper pouring reduces ground impedance and provides shielding protection and noise suppression.

In digital circuits, there are often large amounts of sharp pulse currents, making it necessary to reduce ground impedance. Copper pouring is a common method for this purpose. It can reduce ground resistance by increasing the conductive cross-sectional area of the ground, shorten the length of the ground, reduce ground inductance, and thus lower ground impedance.

It can also control the ground capacitance, appropriately increasing the capacitance value to enhance ground conductivity and reduce impedance. Large areas of ground or power pouring copper can also act as shields, helping to reduce electromagnetic interference, improve circuit immunity to interference, and meet EMC requirements. Additionally, for high-frequency circuits, copper pouring provides a complete return path for high-frequency digital signals, reducing the wiring of DC networks and thereby improving the stability and reliability of signal transmission.

2. Copper Pouring Enhances PCB Heat Dissipation Capability

In PCB design, copper pouring is not only used to reduce ground impedance but also for heat dissipation. As is well known, metals are materials with good electrical and thermal conductivity. Therefore, if copper is poured onto a PCB, there will be more metal components in the gaps and other blank areas of the board, increasing the heat dissipation surface area and making the PCB board easier to dissipate heat overall. Copper pouring can also help evenly distribute heat to prevent the formation of localized high-temperature areas. By evenly distributing heat across the entire PCB board, it is possible to reduce the concentration of local heat, decrease temperature gradients, and improve heat dissipation efficiency. Thus, in PCB design, copper pouring can be utilized for heat dissipation in the following ways:

Designing heat dissipation areas: Based on the distribution of heat sources on the PCB board, design heat dissipation areas reasonably and lay sufficient copper foil in these areas to increase the heat dissipation surface area and thermal conduction paths.

Increasing copper foil thickness: Increasing the thickness of copper foil in heat dissipation areas can increase thermal conduction paths and improve heat dissipation efficiency.

Designing heat dissipation vias: Designing heat dissipation vias in heat dissipation areas can conduct heat to the other side of the PCB board through vias, increasing heat dissipation paths and improving heat dissipation efficiency.

Adding heat sinks: Adding heat sinks in heat dissipation areas can conduct heat to the heat sinks, which then dissipate heat through natural convection or fan heat sinks, thereby improving heat dissipation efficiency.

3. Copper Pouring Can Reduce Deformation and Improve PCB Manufacturing Quality

Copper pouring can help ensure the uniformity of plating, reduce deformation of the board during lamination, especially for double-sided or multilayer PCBs, thereby improving the manufacturing quality of the PCB.

If copper foil is distributed excessively in some areas and insufficiently in others, it can lead to uneven distribution across the entire board. Copper pouring can effectively reduce this disparity.

4.Meeting Special Component Installation Requirements

For certain special components, such as those requiring grounding or with unique installation requirements, copper pouring can provide additional connection points and structural support, enhancing the stability and reliability of the components. Therefore, based on the aforementioned advantages, in most cases, electronic designers choose to pour copper on PCBs. However, copper pouring is not mandatory in PCB design. In some cases, it may not be suitable or feasible. Here are some situations where copper pouring may not be advisable:

High-frequency signal lines: For high-frequency signal lines, copper pouring may introduce additional capacitance and inductance, affecting signal transmission performance. In high-frequency circuits, it’s usually necessary to control the routing of ground lines to minimize the return path of ground rather than excessively pouring copper. For example, pouring copper around antenna sections can lead to significant interference with weak signal acquisition. Antenna signals require very strict amplifier circuit parameter settings, and copper pouring impedance can affect the performance of amplifier circuits. Therefore, copper is generally not poured around antenna sections.

High-density PCBs: Excessive copper pouring on high-density PCBs may cause short circuits or grounding issues between lines, affecting the normal operation of the circuit. When designing high-density PCBs, careful design of copper pouring structures is necessary to ensure sufficient spacing and insulation between lines to avoid problems.

Rapid heat dissipation, soldering difficulties: Fully covering component pins with copper pouring may result in rapid heat dissipation, making desoldering and rework difficult. Copper has high thermal conductivity, so whether it’s manual soldering or reflow soldering, the copper surface quickly conducts heat, causing temperature loss for the soldering iron, which affects soldering. Therefore, it’s preferable to use “cross-shaped solder pads” in design to reduce heat dissipation and facilitate soldering.

Special environmental requirements: In some special environments, such as high temperature, high humidity, or corrosive environments, copper foil may be damaged or corroded, affecting the performance and reliability of PCBs. In such cases, appropriate materials and processing methods should be chosen according to specific environmental requirements rather than excessive copper pouring.

Special-level boards: For special-level boards like flexible PCBs or rigid-flex PCBs, copper pouring design should be done according to specific requirements and design specifications to avoid problems caused by excessive copper pouring on flexible layers or rigid-flex layers.

In summary, in PCB design, it’s necessary to make appropriate choices between copper pouring and not pouring copper based on specific circuit requirements, environmental requirements, and special application scenarios.

How do you add copper pour in Altium?

To add a copper pour in Altium Designer, follow these steps:

1. Open the PCB Layout Editor: After completing your schematic design, switch to the PCB layout editor by clicking on “Design” > “Update PCB Document” or by selecting the PCB document directly from the Projects panel.

2. Select the Polygon Pour Tool: In the PCB Layout Editor, locate the toolbar on the left side of the screen. Click on the “Place Polygon Pour” button, which typically looks like a polygon or rectangle with a pour symbol.

3. Define the Copper Pour Area: Click on the PCB workspace where you want to start the copper pour. Then, click to add points to define the boundary of the pour area. You can create any shape by clicking to add vertices and double-clicking to close the shape.

4. Configure the Copper Pour Properties: After defining the pour area, the Polygon Pour dialog box will appear. Here, you can configure various properties of the copper pour, such as the net name (usually ground or power), layer, clearance, and thermal relief settings. Make sure to set these properties according to your design requirements.

5. Complete the Copper Pour: Once you have configured the pour properties, click “OK” to complete the copper pour. Altium will automatically fill the defined area with copper according to the specified properties.

6. Adjust Pour Properties (if necessary): You can modify the properties of the copper pour at any time by selecting the pour area and accessing its properties from the Properties panel. This allows you to make adjustments to the pour’s net, layer, clearance, and other settings as needed.

7. Update the PCB: After adding or modifying the copper pour, remember to update the PCB document to reflect the changes. You can do this by clicking on “Design” > “Update PCB Document” or by using the shortcut Ctrl + D.

By following these steps, you can add and configure copper pours in Altium Designer to meet the specific requirements of your PCB design.

How do you remove copper pour?

To remove a copper pour in a PCB (Printed Circuit Board) design, you typically follow these steps depending on the PCB design software you’re using:

1. Accessing the Copper Pour: Open your PCB layout software and navigate to the PCB layout where the copper pour is located.

2. Selecting the Copper Pour: Use the appropriate tool to select the copper pour area that you want to remove. This tool is usually labeled as “Copper Pour,” “Polygon Pour,” or something similar.

3. Deleting the Copper Pour: Once the copper pour area is selected, there should be an option to delete or remove it. This action will clear the copper pour from the selected area.

4. Updating the PCB Layout: After removing the copper pour, make sure to update the PCB layout to reflect the changes you’ve made. This typically involves re-pouring the copper or adjusting other elements affected by the removal.

5. Verification: It’s always a good practice to verify the changes made to ensure they haven’t caused any unintended issues or connectivity problems.

6. Save Changes: Once you’re satisfied with the changes and have verified the design, save your work to preserve the modifications.

The specific steps may vary slightly depending on the PCB design software you’re using, so refer to the software’s documentation or help resources for more detailed instructions tailored to your tool.