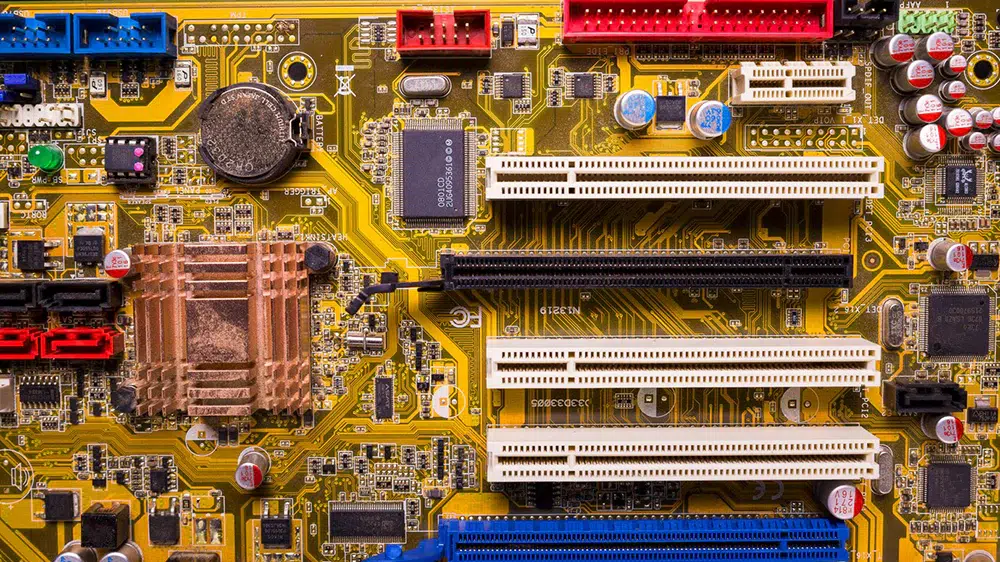

In the world of electronics, efficient communication between various components is crucial for the performance and functionality of devices. One of the key elements facilitating this communication is the backplane printed circuit board (PCB). This article explores the structure, function, design considerations, and applications of backplane PCB, highlighting its importance in modern electronic systems.

What is a backplane PCB?

A backplane PCB is a type of circuit board that serves as a backbone for connecting multiple printed circuit boards (PCBs) or other electronic components. Unlike traditional PCBs that often house active components like microcontrollers or power supplies, backplane PCBs primarily function as a connectivity medium. They typically consist of several connectors and traces designed to route signals and power between different modules.

What is the function of the backplane PCB ?

Backplane PCBs primarily serve the following functions:

Signal Routing: They manage the distribution of data signals between different modules, ensuring that communication occurs seamlessly.

Power Distribution: Backplanes often carry power from a central source to various components, reducing the need for individual power supplies for each module.

Mechanical Support: They provide structural support for the attached modules, ensuring stability and durability in various operational environments.

What is a backplane PCB made of?

A backplane PCB (Printed Circuit Board) is typically made of several key materials:

1. Base Material: The most common base material is FR-4, a fiberglass-reinforced epoxy laminate that provides good mechanical strength and electrical insulation. Other materials, like polyimide or Rogers materials, might be used for high-frequency applications.

2. Copper Layer: The PCB has one or more copper layers that form the circuit traces and pads. The thickness of the copper can vary, but standard thicknesses are usually 1 oz or 2 oz per square foot.

3. Solder Mask: A layer of solder mask is applied to protect the copper traces from oxidation and to prevent solder from bridging between connections during assembly. It typically has a green color, but other colors are also available.

4. Silkscreen: This is a printed layer used for labeling components and providing designators on the PCB, typically in white ink.

5. Mechanical Features: Backplanes often include mechanical features like mounting holes and slots, which may require additional treatments or plating.

Backplanes may also incorporate additional layers for shielding or special functionality, depending on their specific application in systems like telecommunications or data processing.

What is the difference between a backplane PCB and a PCB motherboard?

The terms “backplane PCB” and “PCB motherboard” refer to different types of printed circuit boards, each serving distinct purposes in electronic systems.

Backplane PCB:

1. Function: A backplane PCB primarily serves as a backbone for connecting multiple printed circuit boards (PCBs) or modules. It doesn’t usually contain processing components itself; instead, it provides electrical connections and communication pathways.

2. Structure: Backplanes often have multiple slots or connectors for other cards (like daughterboards) to plug into. They can be used in modular systems where components can be added or removed as needed.

3. Application: Commonly used in telecommunications, servers, and industrial applications where flexibility and scalability are essential.

PCB Motherboard:

1. Function: A motherboard is a central PCB that hosts the main components of a computer or device, including the CPU, RAM, and other essential circuitry. It acts as the primary platform for integrating and managing all hardware components.

2. Structure: Motherboards include various integrated components and interfaces (like USB ports, power connectors, etc.) and usually feature a complex layout to connect these components effectively.

3. Application: Found in personal computers, laptops, and many electronic devices, serving as the main hub for all operations.

Summary:

In essence, while a backplane is designed primarily for connectivity and modularity, a motherboard integrates and manages core components of a device. Each plays a crucial role in its respective applications.

How thick is the backplane PCB?

The thickness of a backplane PCB can vary depending on its design and specific application requirements, but common thicknesses range from 1.6 mm (0.062 inches) to 3.2 mm (0.125 inches).

For standard applications, a thickness of 1.6 mm is typical. However, thicker backplanes might be used for increased mechanical strength or to accommodate higher current requirements. Custom backplane designs may also utilize different thicknesses based on specific needs, such as thermal management or high-frequency performance. Always refer to design specifications for the exact requirements for a particular backplane.

What types of connectors are used on backplane PCB?

Backplane PCBs utilize various types of connectors to facilitate connections between the backplane and the modular cards or components. Some common types of connectors include:

1. Edge Connectors: These are often used in backplane designs, allowing cards to plug directly into the backplane. They typically feature a row of gold-plated contacts along one edge of the card.

2. DIN Connectors: These circular connectors are commonly used in industrial applications for their robustness and reliability.

3. D-Sub Connectors: Known for their distinctive D-shaped metal shells, these connectors can provide multiple signal and power connections.

4. PCI Express (PCIe) Connectors: Used in modern computing applications, these connectors support high-speed data transfer and are designed for specific card types.

5. SATA Connectors: Typically used for connecting storage devices, SATA connectors can also be found on backplanes in storage systems.

6. Molex Connectors: Commonly used for power connections, these connectors can provide reliable power distribution to multiple cards.

7. RJ45 Connectors: Used for Ethernet connections, these connectors are employed in backplanes for networking applications.

8. BNC Connectors: Often used for coaxial cables in RF applications, these connectors can also be found on some specialized backplane designs.

The choice of connectors depends on the specific application, including factors such as required data rates, power needs, and the type of modules being connected.

Conclusion

Backplane PCBs play an essential role in the functionality and efficiency of modern electronic systems. Their ability to facilitate communication and power distribution between various components makes them indispensable in numerous applications, from telecommunications to consumer electronics. As technology continues to evolve, the design and capabilities of backplane PCBs will likely advance, further enhancing the performance of electronic devices. Understanding their significance is crucial for engineers and designers aiming to create reliable and efficient electronic systems.

A backplane PCB is a type of circuit board that serves as a backbone for connecting multiple printed circuit boards (PCBs) or other electronic components.

Backplane PCBs primarily serve the following functions:

Signal Routing: They manage the distribution of data signals between different modules, ensuring that communication occurs seamlessly.

...

A backplane PCB (Printed Circuit Board) is typically made of several key materials:

1. Base Material: The most common base material is FR-4, a fiberglass-reinforced epoxy laminate that provides good mechanical strength and electrical insulation. Other materials, like polyimide or Rogers materials, might be used for high-frequency applications.

...