In the world of electronics and manufacturing, the terms Contract Electronics Manufacturing (CEM), Electronics Manufacturing Services (EMS), Original Equipment Manufacturer (OEM), and Original Design Manufacturer (ODM) refer to different aspects of the production and design process. Understanding the distinctions between these terms is crucial for companies seeking to optimize their manufacturing strategies and partnerships. Here’s a detailed explanation of each term and their differences:

Contract Electronics Manufacturing (CEM)

Contract Electronics Manufacturing (CEM) refers to the practice of outsourcing the production of electronic components or devices to a third-party company that specializes in manufacturing services.

Key Characteristics:

– Service-Based: CEM providers focus on manufacturing and assembly services based on the specifications and designs provided by their clients.

– Client-Driven Design: The design and engineering of the product are typically provided by the client, and the CEM focuses on executing the production.

– Flexibility: CEMs often provide a range of services including component sourcing, assembly, testing, and logistics.

– Customization: CEMs adapt their manufacturing processes to the client’s specific requirements, often working with various designs and product types.

Example:

A company that designs its own electronic product might use a CEM to assemble the product, test it, and handle logistics, while the client manages the design and product development.

Electronics Manufacturing Services (EMS)

Definition:

Electronics Manufacturing Services (EMS) refers to a type of contract manufacturing where a company provides a comprehensive suite of services for the production of electronic products.

Key Characteristics:

– Broad Service Offering: EMS providers offer a wide range of services, including design, manufacturing, assembly, testing, and after-market services.

– Flexibility and Scalability: EMS providers are equipped to handle varying production volumes, from prototypes to large-scale manufacturing.

– Value Addition: EMS companies often add value through their expertise in manufacturing processes and supply chain management.

Example:

An EMS provider might handle the entire lifecycle of an electronic product for a client, from initial design support and prototyping to full-scale production and distribution.

Original Equipment Manufacturer (OEM)

Definition:

An Original Equipment Manufacturer (OEM) refers to a company that produces products or components that are then sold to other companies, which may use them in their own products or sell them under their brand name.

Key Characteristics:

– Brand and Product Focus: OEMs focus on producing products that are branded and marketed by other companies.

– Design Ownership: OEMs typically manufacture products according to specifications provided by other companies, which may be the ones that own the brand and product design.

– Volume Production: OEMs often operate on a large scale to produce components or complete products in high volumes.

Example:

An OEM might manufacture computer components such as motherboards or memory modules that are then integrated into computers by other companies, which sell the final product under their own brand.

Original Design Manufacturer (ODM)

Definition:

An Original Design Manufacturer (ODM) is a company that not only manufactures products but also designs them. ODMs produce products based on their own designs or modify existing designs to meet the requirements of their clients.

Key Characteristics:

– Design and Manufacturing: ODMs provide both design and manufacturing services, offering a more integrated approach compared to traditional CEMs and OEMs.

– Turnkey Solutions: ODMs often provide complete solutions, including design, prototyping, and manufacturing, which can be branded by the client.

– Innovation: ODMs may offer innovative design solutions and help clients bring new products to market more quickly.

Example:

A company might collaborate with an ODM to create a new consumer electronics product. The ODM would handle the entire process, from designing the product to manufacturing and delivering it, allowing the client to market the product under their own brand.

Summary

– Contract Electronics Manufacturing (CEM): Focuses primarily on manufacturing and assembly based on client-provided designs. Offers flexibility in handling different designs and production scales.

– Electronics Manufacturing Services (EMS): Includes a broad range of services from design and prototyping to full-scale production and logistics. Often provides additional value through supply chain management and manufacturing expertise.

– Original Equipment Manufacturer (OEM): Produces components or products based on designs provided by other companies, which then brand and market the products. Focuses on high-volume production.

– Original Design Manufacturer (ODM): Provides both design and manufacturing services. Offers turnkey solutions and often handles the complete product lifecycle from design to production, which can be branded by the client.

Understanding these distinctions helps companies choose the right type of manufacturing partner based on their needs, whether they require design, manufacturing, or a combination of both.

A Professional OEM/ODM/EMS Manufacturer ---IBE Electronics

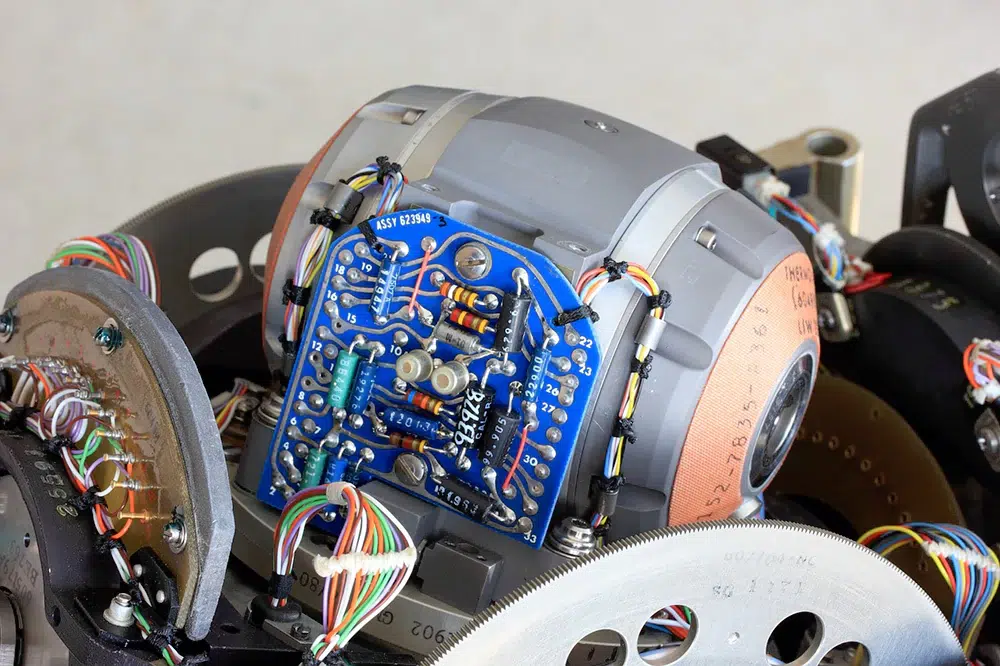

IBE is a professional OEM/ODM/EMS service provider since 2005 and specializing in turn-key solution including Electronic design and engineering, PCB fabrication, SMT and PCB assembly, components sourcing, prototyping, testing and other value-added services.

To provide better customer service and local technical support, we built EMS&OEM/ODM base in Bac Ninh, Vietnam, and R&D&EMS base in Milpitas US respectively. The total area of all the production facilities covers more than 90,000 square meters, equipped with EVT/DVT/PVT, laboratory and test centers. IBE has established a strong R&D team with more than 80 senior professionals with master’s degree or above, and obtained IATF16949,ISO13485,ISO9001,ISO14001, ISO45001 and UL certification.