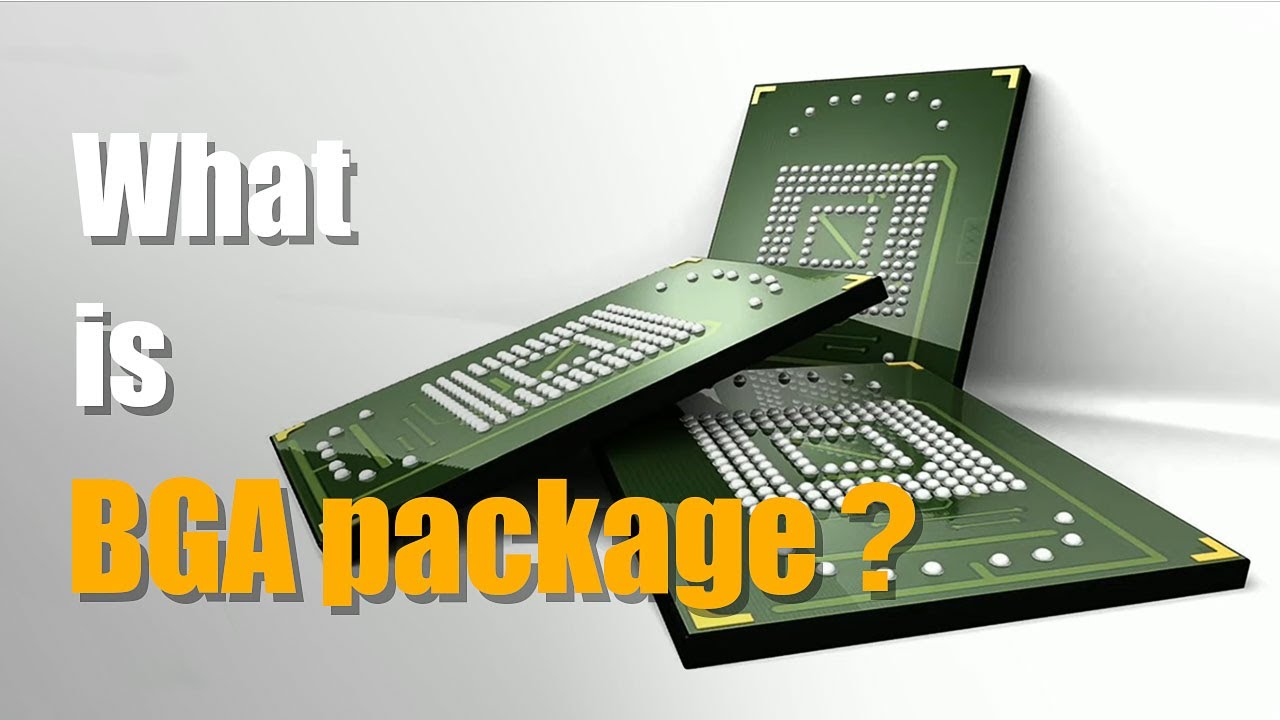

BGA (Ball Grid Array) chips are a surface mount technology that uses a special array of solder balls to connect to the board instead of traditional pins. The BGA soldering process requires fine operation and specialized equipment, the following are detailed BGA soldering process.

Ⅰ. Preparation

1. Working environment:

BGA soldering needs to be carried out in a clean, dust-free and constant temperature environment. The working area should be cleaned and maintained regularly to ensure the soldering quality and long-term stable operation of the equipment.

2.Tool preparation:

The main tools required for BGA soldering include soldering station, tweezers, soldering iron, suction nozzle, gloves, etc. The soldering station is a fixed operating platform for fixing BGA chips. Tweezers and suction nozzles are used to handle BGA chips and solder balls. A soldering iron and heat gun are used to heat and melt the solder.

3. Material preparation:

In addition to BGA chips and solder balls, some other materials are required, such as flux, solvent and cleaning agent. Fluxes are used to increase the activity of the solder, solvents are used to wash and remove excess solder, and cleaning agents are used to clean the board after soldering.

Ⅱ. Install the BGA chip

1. Put the BGA chip on the soldering station and make sure it is in the correct position. Note that the edges of the BGA chips should be clear and not damaged or bent.

2. Use tweezers and a suction nozzle to take out an appropriate amount of solder balls, and place them near each pin of the BGA chip. Typically, 8-12 solder balls should be placed around each pin.

Ⅲ. Preheating soldering station

Connect the soldering iron to the soldering station, then turn on the power and preheat the station to the proper temperature. Note that the preheating temperature should be higher than the melting point of the BGA chip, but lower than the melting temperature of the solder.

Ⅳ. BGA soldering process

1. Pick up the prepared BGA chip and put it on the soldering position. Use tweezers and a suction nozzle to stick solder balls to each pin of the BGA chip.

2. When all the solder balls are pasted, start heating the BGA chips and solder balls. Usually, the initial temperature should be slightly higher than the melting temperature of the solder to help the solder wet and flow between the pins.

3. When the solder starts to melt, gradually increase the temperature until it reaches the melting temperature of the solder. During the melting process, it is necessary to maintain a steady pressure on the BGA chips and solder balls to prevent them from moving or tilting.

4. When all the solder is melted and filled to the gap between the pins, continue heating for a while to fully harden and fix the solder.

Ⅴ. Cooling and inspection

1. Immediately turn off the power, and use a suction nozzle and gloves to remove the BGA chip after the soldering is completed. At this point, the solder is still very hot and may burn your hands, so special care is required.

2. Let the BGA chips cool naturally at room temperature. During cooling, the solder solidifies and fixes, forming a stable electrical connection.

3. After cooling, open the printed circuit board and check if there is any solder overflow or short circuit. If there is, the solder needs to be removed with solvents and cleaners and soldered again.

Ⅵ. Post-processing

1. During the whole BGA soldering process, it is necessary to check and replace the soldering iron tip regularly to ensure the soldering quality. At the same time, the working environment needs to be cleaned and maintained regularly.

2. After completing soldering, BGA chips and circuit boards should be properly packaged and stored to prevent secondary pollution and mechanical damage.

Although the BGA soldering process is complicated, as long as the steps and precautions are strictly followed, high-quality soldering results can be obtained. I hope this article can help you understand and master the BGA soldering process.