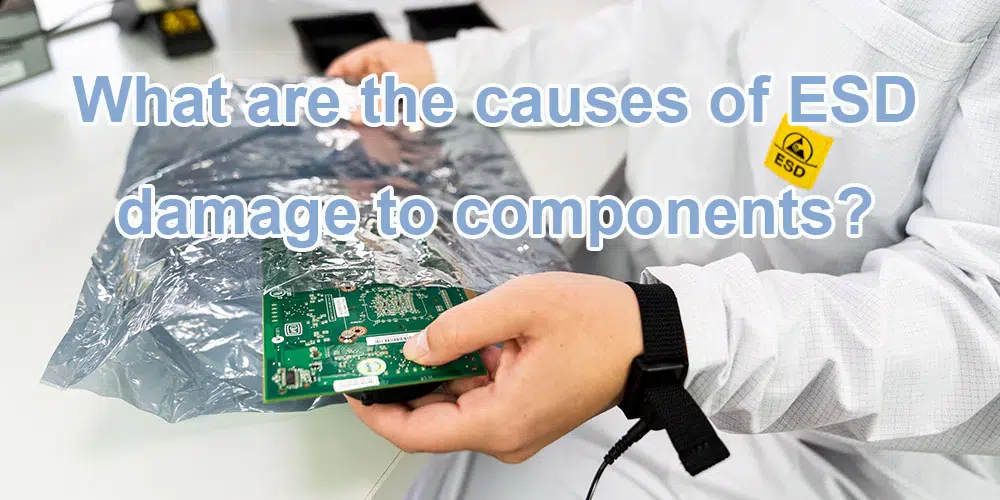

On the PCB assembly line, workers are assembling sensitive electronic components onto printed circuit boards. When workers touch sensitive components or circuit boards with electrostatically charged hands, the electrostatic charges will be quickly discharged, generating high-energy currents, which could damage the component’s internal electronics, causing the component to function incorrectly or fail completely.

What is ESD damage to components?

ESD damage to components means that during electrostatic discharge, high-energy current passes through components to cause damage or failure. ESD damage is usually caused by the accumulation and discharge of static electricity, which is caused by the difference in charge between electrons. When electrostatic charge builds up to a high enough level on components, they can discharge at a very rapid rate, releasing enormous amounts of energy. ESD damage can have the following effects:

The high-energy current generated by electrostatic discharge may damage or burn the electronic components inside the components and devices. This may cause the component not to function properly or to fail completely.

ESD damage to components may lead to a decrease in their functional performance or complete failure. This may affect the overall performance of the device or system, or even prevent the device from functioning properly.

After static electricity damages components, it may be necessary to repair or replace damaged components. This will increase repair costs and repair time, especially for expensive, complex or not readily available components.

If static electricity damages components during the production process, it may cause production line shutdown or delay. This causes interruptions to production planning, delivery delays, and additional costs and resource consumption.

What are the causes of ESD damage to components?

The following are some factors that may cause static electricity to damage components:

1. Static electricity accumulation: When friction or separation occurs between two objects, static electricity accumulation will occur. This means that one object has too much charge and the other has the opposite charge or relatively little charge. When these charged objects come into contact with or come close to electronic components, static electricity can discharge rapidly, causing a brief but high-energy current to flow through the component, causing damage.

2. Static electricity on human body: the human body can also become a carrier of static electricity. When the human body rubs or separates from the ground or other charged objects, it can cause the human body to become electrostatically charged. When the human body comes into contact with sensitive electronic components, static electricity can discharge through the human body to the components, causing damage.

3. Improper handling: When handling electronic components, it is easy to cause electrostatic discharge and cause damage to components.

How to control ESD damage to components?

1. Static protection measures: Establish a static-safe working environment, including the use of anti-static workbenches, floors and tools. Make sure staff wear anti-static clothing, such as anti-static gloves, shoes, and clothing. These measures help prevent the build-up and discharge of static electricity.

2. Electrostatic discharge device: Use an electrostatic discharger or grounding device to discharge static electricity. These devices safely discharge accumulated static electricity to ground or a grounding point, reducing the risk of damage to components.

3. Static electricity eliminators: Use static electricity eliminators to neutralize or eliminate charges, which typically use a high-voltage ionizer to generate ions that neutralize positive and negative charges, thereby reducing the presence of static electricity.

4. Anti-static packaging: For sensitive electronic components, use anti-static packaging for storage, transportation and handling. This kind of packaging is usually made of conductive or antistatic materials, which can effectively isolate components and prevent ESD damage.

5. Regular inspection and maintenance: Regularly check the effectiveness of electrostatic protection equipment and tools, and carry out necessary maintenance and replacement. Ensure that equipment and tools are well grounded and repair any damage or malfunction promptly.

7.Design optimization: In the design stage of components and circuit boards, some optimization measures can be taken to reduce the risk of ESD damage, such as adding electrostatic protection circuits, using anti-static materials, and rationally laying out circuit boards, etc.

Static electricity is a common hidden danger in electronic components, but as long as effective preventive measures are taken, electronic components can be prevented from being damaged by static electricity. If electronic components have been broken down by static electricity, different repair or replacement methods can be used to solve the problem according to the specific situation.