This article will briefly introduce thick copper PCB and list 10 thick copper PCB manufacturers.

About thick copper PCB

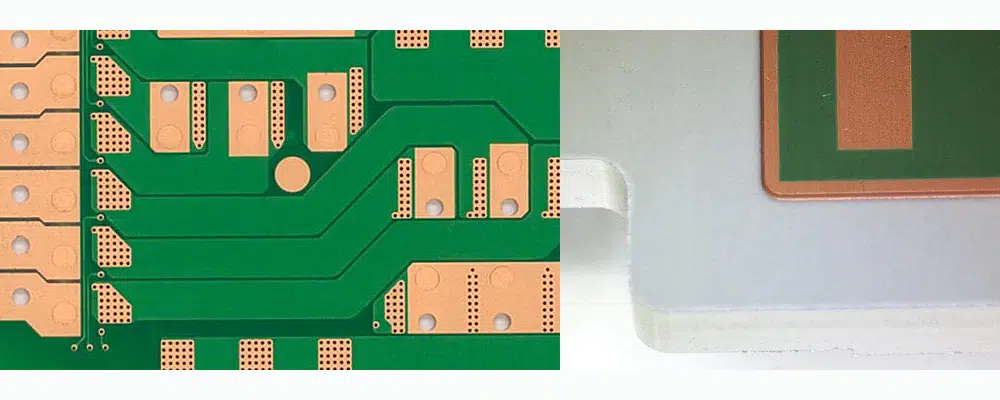

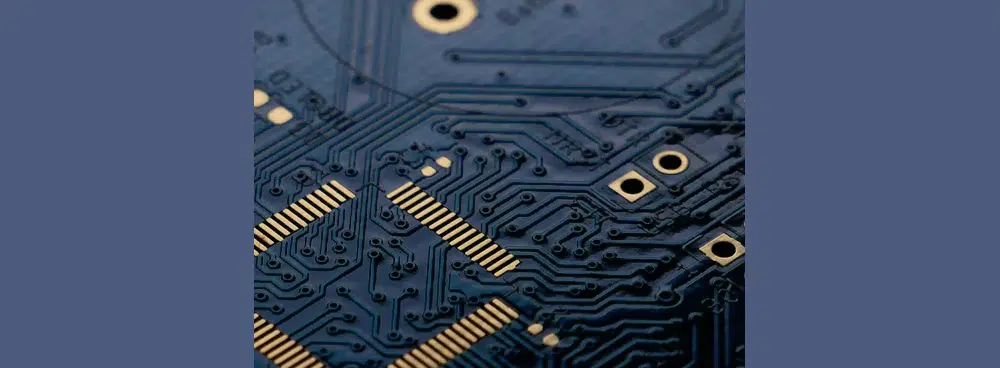

Copper thickness refers to the thickness of copper foil, which is a thin, continuous layer of metal foil deposited on the base layer of the circuit board. It is used for conductive conduction of the PCB. Copper thickness is divided into inner layer copper thickness and outer layer copper thickness, which are measured in weight unit oz. Generally, the copper thickness of single-sided and double-sided PCBs is 1oz; the outer layer of multi-layer boards is generally 1oz and the inner layer is 0.5oz.

A high-current PCB or thick copper PCB contains 3 ounces or more of copper in the outer and inner layers of the board. Thick copper plates are applicable to a wide range of fields, including mobile phones, microwaves, aerospace, satellite communications, network base stations, hybrid integrated circuits, power supply high-power circuits and other high-tech fields. Thick copper plates have excellent elongation properties, are resistant to high and low temperatures, and are resistant to corrosion. They allow electronic equipment products to have a longer service life and are also very helpful in simplifying the size of electronic equipment. In particular, electronic products that need to run higher voltages and currents require thick copper plates.

Performance of thick copper PCB

Thick copper PCBs have the characteristics of carrying large current, reducing thermal strain, and good heat dissipation. It is not limited by the processing temperature. Oxygen blowing can be used when the melting point is high, and it is not brittle at low temperatures. It is also fireproof and is a non-combustible material. Even in extremely corrosive atmospheric environments, copper sheets form a strong, non-toxic passivation protective layer.

Advantages of thick copper PCB

Thick copper PCBs have a lot to offer. It has some unique features that make it ideal for high-end applications.

Huge Thermal Distribution: This PCB offers high thermal resistance due to its copper-plated through-holes. Thick copper PCBs are used in applications requiring high speed and high frequency. You can also use this PCB in harsh temperatures.

Mechanical Strength: Thick copper PCB has high mechanical strength. When this type of PCB is used, it makes the electrical system durable and strong.

Good conductor: Thick copper circuit boards are good conductors. Due to this property, they are used in the production of electronic products. They help connect various boards together. These plates can pass electrical current.

On-board heat sink: Thick copper plate provides on-board heat sink. Using these panels you can achieve an effective heat sink on a mosaic surface.

Huge dissipation coefficient: Thick copper PCBs are ideal for large components with high power dissipation. These PCBs prevent electrical systems from overheating. They dissipate heat efficiently.

Supports special materials: Thick copper helps protect and enhance special materials. Special materials are sometimes used to design electronic components. Extreme temperatures may require an special material. Thick copper plates put an end to circuit failures because they use an special material to fully function.

10 thick copper PCB manufacturers in the world

| Headquarters | Kanagawa, Japan |

| Established time | 1975 |

| Company website | https://www.meiko-elec.com/english/ |

Meiko Electronics is a Japan-based company mainly engaged in the electronics-related business. Meiko provides a wide range of services, including design and manufacturing of printed circuit boards, component mounting and assembly.

Certifications : ISO 9001, ISO 14001, ISO 27001 and ISO/TS 16949

Products

HDI PCB

AnyLayer PCB

Rigid-Flex PCB

High Layer Count PCB

Heavy Copper PCB

Metal Base Heat Dissipation PCB

Embedded Devices PCB

Double-sided/Multi-Layer PCB

High Frequency Millimeter-wave PCB

FR4-FLEX/M-VIA Flex®

FPC

Copper Inlay PCB

TTM

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

| Headquarters | |

| Established time | 1998 |

| Company website | https://www.ttm.com/en |

TTM is a leading global RF and specialty components, advanced technology, and PCB fabrication solutions supplier.

TTM Technologies is a leading global manufacturer of technology solutions including mission systems, radio frequency (“RF”) components and RF microwave/microelectronic assemblies and quick-turn and technologically advanced printed circuit boards (“PCBs”). TTM was incorporated in 1998 and has experienced growth and profitability that has catapulted company into an industry leader in technology solutions and PCB manufacturing. TTM supports our customers at all stages of the product lifecycle, from inception to prototype to high-volume production.

Certifications: UL, ISO 9001 and AS 9100, military and aerospace certification, ITAR compliant, ISO 13485, IATF 16949, IPC 1791 and ACCREDITED NADCAP certifications.

Product

Printed circuit board

RF and speciality components

RF and microwave

microelectronics

Signal integrity

System integration

Engineering and design

| Headquarters | Taoyuan City, Taiwan,China |

| Established time | 1997 |

| Company website | https://www.nanyapcb.com.tw/nypcb/english/index.aspx |

Nan Ya Printed Circuit Board Corp is a Taiwan-based company principally engaged in the manufacture and sales of printed circuit boards (PCBs). Nan Ya PCB Corporation used to be one of the business divisions of Nan Ya Plastics Corporation which is part of Formosa Plastics Group and turned into a subsidiary by 1997 as the manufacturer of Printed Circuit Boards (PCBs) and IC Substrates.

Certifications: ISO-45001, SONY GP, ISO-9001, ISO/CNS-14001 and IATF 16949

Product: PCB, IC substrate

AT&S

| Headquarters | Leoben, Austria |

| Established time | 1987 |

| Company website | https://ats.net/en/company/ |

AT & S Austria Technologie & Systemtechnik AG engages in the development, manufacture, and trade of printed circuit boards (PCB) and IC substrates. It operates through the following segments: Mobile Devices and Substrates; Automotive, Industrial, Medical; and Others. The Mobile Devices and Substrates segment produces and supplies PCBs for mobile end-users such as smartphones, tablets, notebooks, and consumer products such as digital camera as well as substrates for desktop PCs and servers. The Automotive, Industrial, Medical segment supports a range of customers in the field of automotive supplies, industrial applications, medical technology, aerospace, security, and other sectors. The Other segment deals with the corporate and holding activities. The company was founded in 1987 and is headquartered in Leoben, Austria.

Certification: ISO 9001:2015, IATF 16949:2016, AS/EN 9100:2018, ISO 13485:2016, NADCAP-Accreditation , ANSI ESD S20.20 and ISO/IEC 27001:2013.

Product

IC substrates

Substrate-like printed circuit boards and modules

Flexible and rigid-flex printed circuit boards

Thermally enhanced printed circuit boards

Cavity printed circuit boards

HDI printed circuit boards

ECP printed circuit boards

High-frequency & high-speed printed circuit boards

Multilayer printed circuit boards

Test & reference boards

Double-sided printed circuit boards

SCC

| Headquarters | Shenzhen,China |

| Established time | 1984 |

| Company website | https://www.scc.com.cn/scc/en/index.html |

Shennan Circuits Co., Ltd. (hereinafter referred to as “SCC”), founded in 1984 , is headquartered in Shenzhen, Guangdong, China.

After years of development, SCC has established a long-term and stable strategic cooperative relationship with the world’s leading communication equipment manufacturers and medical equipment manufacturers. It has become a key high-tech enterprise of the national torch plan, the first national technological innovation demonstration enterprise and national enterprise technology center in the printed circuit board industry, a leading enterprise in China’s printed circuit board industry, a pioneer in China’s packaging substrate field, and an advanced enterprise in electronic assembly manufacturing, The chairman unit of China Electronic Circuit Industry Association (CPCA) and the chairman unit of the Standards Committee have led or participated in the formulation of a number of industry standards.

Certifications : ISO9001, ISO/TS16949, AS9100, Nadcap, and ISO13485.

Product: PCB, PCBA, SUB, SIP…

| Headquarters | Minato-ku, Tokyo |

| Established time | 1969 |

| Company website | https://www.mektron.co.jp/company_e/company_profile_e/ |

Nippon Mektron, Ltd. began in November 1969 in Kukizaki Village (now Tsukuba City), Ibaraki Prefecture, as the flexible printed circuit board (FPC) manufacturing subsidiary of NOK Corporation.Nippon Mektron Ltd. manufactures electronic products. The Company designs, manufactures, and sells single-sided and double-sided circuit boards.

Product

Single-Side FPC

Double-sided FPC

Multi-layer FPC(FLEXBOARD)

Component Assembly FPC

High Speed Transmission FPC

Automotive FPC

Precision Parts For HDD

Precision Parts For Mobile

FPC with Waterproof Function Parts

For Automotive

For Wearable device

Wus

| Headquarters | Taiwan,China |

| Established time | 1972 |

| Company website | https://www.wus.com.tw/index.php/en/ |

Established in 1972 by the name of WUS (Wu-Shi), the predecessor of WUS Printed Circuit Co., Ltd., the progress of the company’s products and their applications was significantly linked and fueled by the economic growth of Taiwan in the electronics arena. These applications included add-on cards (peripherals), motherboards, telecom products, and eventually to radio base stations, mobile phones, digital cameras, notebooks, and other digital and entertainment products.

Certifications : ISO9001 ,ISO 14001,OHSAS 18001/ISO 45001,ISO/TS16949, IECQ QC080000 HSPM, Sony Ericsson GP Approval, ISO 13485, ISO 5000,AS9100 and ISO 14064

Besides core products like multilayer and mobile phones boards, the company technologically moved into advancements such as communication (RF) modules, embedded passives, and high-density microvia (HDI) products in order to differentiate from the advanced field to the traditions.

Glorysky Elektronic

| Headquarters | Shenzhen,China |

| Established time | 2000 |

| Company website | https://www.glorysky.de/ |

Glorysky Electronic Group was established in 2000 in Shenzhen, China, back then we were a PCB retailer with a single office in Shenzhen. Glorysky provides the most advanced PCB technical solutions and best-in-class PCB products for the global key automotive electronics, communication, lighting, industry control, health care and security brands.

Certifications: Glorysky is ISO 9001, ISO 14001, ISO13485, IATF 16949, GJB9001B, UL and Canana, RoHS, REACH and other international certifications qualified.

Products: Glorysky is a leading PCB manufacturer and provides global customer single & double sided, multi layer, highly advanced HDI, flex, rigid-flex and high-frequency boards.

| Headquarters | Taiwan.China |

| Established time | 1990 |

| Company website | https://www.unimicron.com/en/ |

Unimicron Technology Corporation is a printed circuit board manufacturer headquartered in Taiwan. The company produces PCBs, high density interconnection boards, flexible PCBs, rigid flex PCBs, integrated circuit carriers, and others. In addition, it provides testing and burn-in services of IC substrates and PCBs.

Certification: NQA(18th)Individual Award, QC080000, TS 16949 : 2002, CNS 15506,NQA (16th)

TL 9000, OHSAS 18001, ISO 9001 : 2000, ISO 14001, ISO 9002 : 1994 and QS 9000.

Product

PCB

IC Carrier

Connector

TP & ECRM

| Headquarters | CA , United States |

| Established time | 1982 |

| Company website | https://www.sierraassembly.com/ |

Sierra Assembly Technology Inc. sprouted from humble roots in 1982, operating with one simple pick and place machine in a 7,000 square foot building. They have since more than tripled the square-footage of our working space, now running two fully automated SMT assembly lines in the 20,000 square-foot complex

Certifications:

AS9100 REV-D+ISO-9001-2015 Certified by SAI Global

ISO 13485 Compliance

IPC-610 & J-STD-001 Compliance

IPC-WHMA-A-620 Compliance

IPC-CC-830B Compliance

All assemblies built to IPC-A-610-D and ANSI/J-STD-001 standards – Class II and Class III

SBA certified, minority-owned, small business

Product : PCB fabrication and PCB assembly