In the PCBA (Printed Circuit Board Assembly) production process, testing is a critical step to ensure the quality and performance of the circuit boards. MDA (Manufacturing Defects Analyzer) testing and ICT (In-Circuit Test) are two common testing methods, and they have significant differences in their definitions, principles, applications, and characteristics. Here’s a detailed explanation of these two testing methods and their differences.

1. Definition and Characteristics of MDA Testing

Definition:

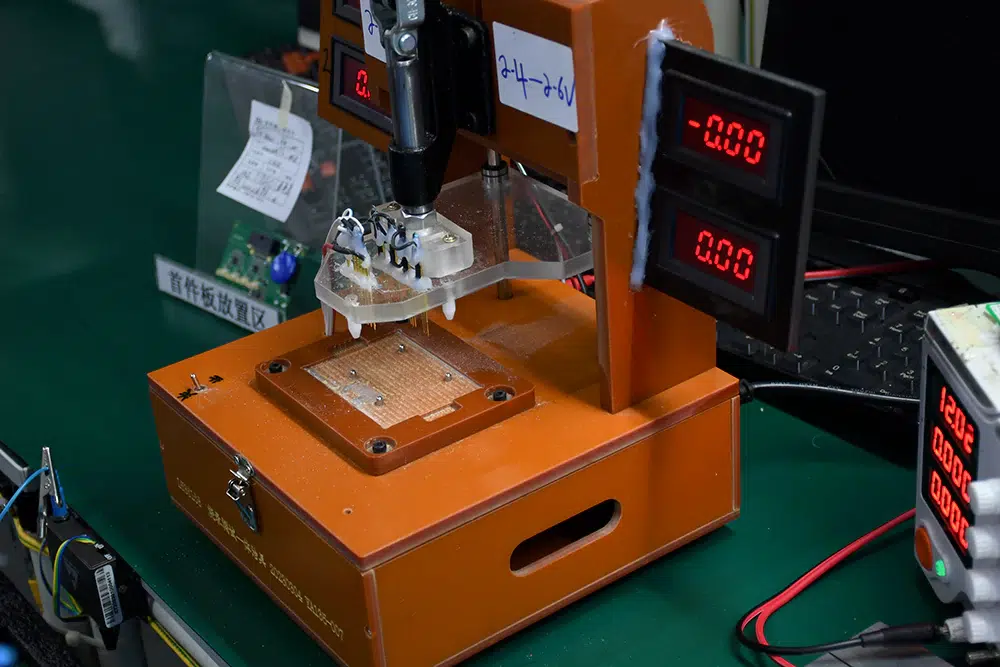

MDA testing, which stands for Manufacturing Defects Analyzer, is a standard testing method used to check for manufacturing defects and component issues by testing the electrical performance and connections of components on the PCB. MDA testing uses sophisticated equipment to inspect each component on the circuit board individually, identifying defects such as open circuits, short circuits, missing components, soldering issues, polarity reversals, and component misalignment.

Characteristics:

– Precision: MDA testing can accurately measure the actual values of each component on the circuit board, including resistance, capacitance, and inductance, ensuring that component performance meets design specifications.

– Efficiency: The testing process is highly automated, allowing for the rapid inspection of a large number of components, thus increasing production efficiency.

– Accurate Fault Localization: MDA testing provides precise location of faults on the circuit board, facilitating subsequent repairs and component replacements.

2. Definition and Characteristics of ICT Testing

Definition:

ICT testing, which stands for In-Circuit Test, is a method that involves using test probes to contact test points on the PCB to check the continuity of circuits, voltage, current values, waveform characteristics, amplitude, noise, and other electrical performance metrics. ICT testing is similar to using a multimeter, allowing for the inspection of all components on the circuit board without the need to disassemble electronic parts.

Characteristics:

– Comprehensive: ICT testing covers all components and circuit networks on the PCB, ensuring thorough inspection.

– Speed: The testing process is fast and efficient, significantly reducing the time required for test initiation and downtime on the production line.

– Accuracy: Controlled by computer programs, ICT testing greatly reduces the risk of false positives or missed defects, improving testing accuracy.

3. Differences Between MDA Testing and ICT Testing

1. Testing Principles

– MDA Testing: This method primarily tests the electrical performance and connections of components on the PCB to identify manufacturing defects and component issues. MDA testing accurately measures each component’s actual values, including resistance, capacitance, and inductance.

– ICT Testing: This method uses test probes to contact test points on the PCB to check circuit continuity, voltage, current values, and other electrical performance characteristics. ICT testing achieves its goals by connecting test points arranged on the PCB via a bed of nails.

2. Testing Scope

– MDA Testing: Focuses on testing the electrical performance and connections of individual components, identifying defects such as open circuits, short circuits, missing components, soldering issues, polarity reversals, and component misalignment.

– ICT Testing: Covers the entire circuit board, including all components and circuit networks. It can detect issues related to component values, connectivity, and polarity across the board.

3. Testing Accuracy

– MDA Testing: Offers high accuracy due to its ability to directly measure the actual values of components.

– ICT Testing: While it has a broad testing range, it may not be as precise as MDA testing in detecting certain subtle electrical performance issues.

4. Cost and Complexity

– MDA Testing: The cost of equipment and fixtures is relatively high, especially for advanced MDA devices, but it offers higher testing accuracy and efficiency.

– ICT Testing: Generally has lower equipment and fixture costs, making it suitable for quality control in high-volume production. However, ICT testing often requires specialized testing equipment and fixtures, adding to its cost and complexity.

5. Application Scenarios

– MDA Testing: More suitable for testing circuit boards where high component performance is required, such as in the production of high-precision electronic products.

– ICT Testing: Widely used in the PCBA production process for various electronic products, enabling quick detection of manufacturing defects and improving product yield.

Conclusion

In summary, MDA testing and ICT testing each play crucial roles in the PCBA production process. MDA testing is valued for its precision and efficiency in high-end electronics production, while ICT testing is appreciated for its comprehensive and rapid inspection capabilities in large-scale manufacturing. Companies should select the appropriate testing method based on product characteristics and production needs to ensure the quality and performance of their circuit boards.