Sheet metal is a versatile material used across industries from aerospace to construction due to its durability, strength and lightweight properties.

This guide will overview what exactly sheet metal is, types of metals used, standard thicknesses, key benefits, applications and how to find custom fabrication services near you.

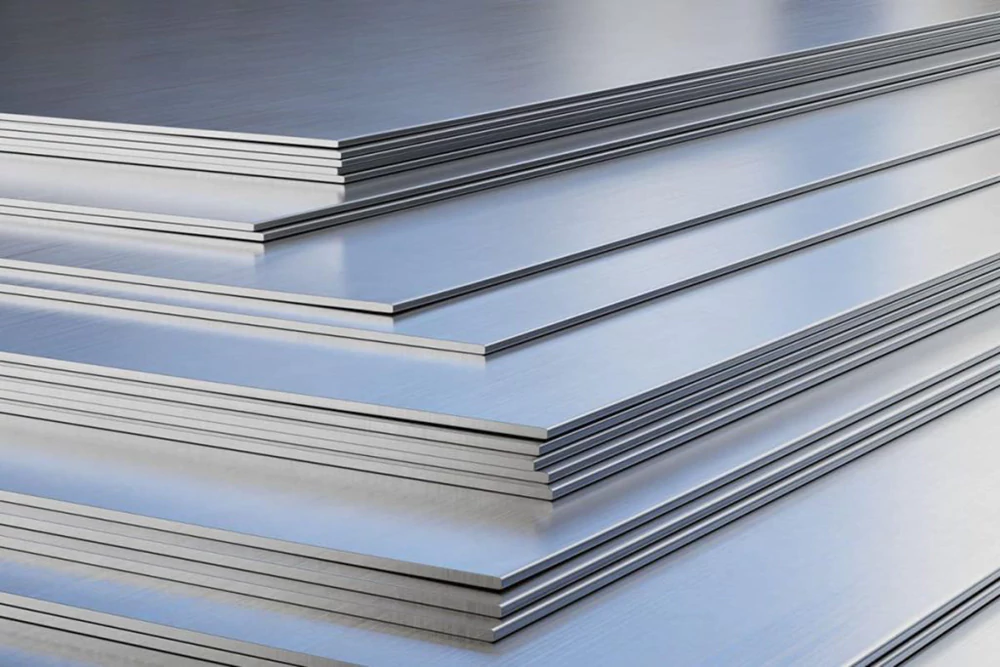

What is Sheet Metal?

Sheet metal refers to metal that has been formed into thin, flat pieces or sheets. The thickness of sheet metal is 0.5mm to 6mm. So it is much thinner than a metal block or bar. Sheet metal maintains uniform thickness along with mechanical strength after the fabrication process like bending or deep drawing.

What is Classified as Sheet Metal?

Sheet metal is defined based on the thickness of the metal sheets. According to industry standards, the thickness of metals qualifying as sheet metal ranges from 0.5mm to 6mm (0.02” to 0.25”).

Metals above 6mm thickness are considered metal plates. While metal foils under 0.5mm thickness have different classifications altogether and face handling considerations during fabrication.

Within the 0.5mm to 6mm range, metal sheets are further classified into light, medium and heavy gauges:

Light Gauge: 0.5mm to 3mm

Used where light weight and easier formability is key such as electronics enclosures. Can bend using hand braces too.

Medium Gauge: 3mm to 5mm

Provides greater structural strength. Used for low-stress areas in automobile bodies and building cladding. Require machinery for bending and cutting.

Heavy Gauge: 5mm to 6mm

Very high tear strength but harder to cut and form. Used for load bearing parts in trucks, ships and construction equipment. Need specialized fabrication tools.

What constitutes sheet metal also depends on the type of metal. For example 3mm aluminum sheet qualifies as heavy gauge while the same thickness in steel is light gauge. The key deciding metrics are workability and structural integrity.

Is Sheet Metal the Same as Steel?

Sheet metal is a broad term for metal formed into thin flat pieces whereas steel refers to a specific metal alloy with high iron content. So all steel when made into sheets is a type of sheet metal. However, not all metals used for sheet fabrication are steel. Other alloys like aluminum and copper are also popularly deployed for specialized sheet metal applications.

What are Common Sheet Metal Materials?

Some commonly used sheet metal materials and their characteristics include:

1. Mild Steel – The most common and cost-effective option. Provides good strength and welding properties. Used for automobile bodies, pipes, ship hulls etc.

2. Stainless Steel – Offers very high corrosion resistance along with durability. Used for kitchen equipment, chemical tanks and medical devices. Grades include 304 and 316 stainless.

3. Aluminum – Extremely lightweight yet strong metal. Easily workable for complex fabrication. Used for aircraft parts, aluminum foil, truck bodies etc. 6061 is a popular alloy.

4. Copper – Highly conductive hence deployed for electrical systems. Also corrosion resistant for roofing. Common as brass (copper + zinc) and bronze (copper + tin) alloys.

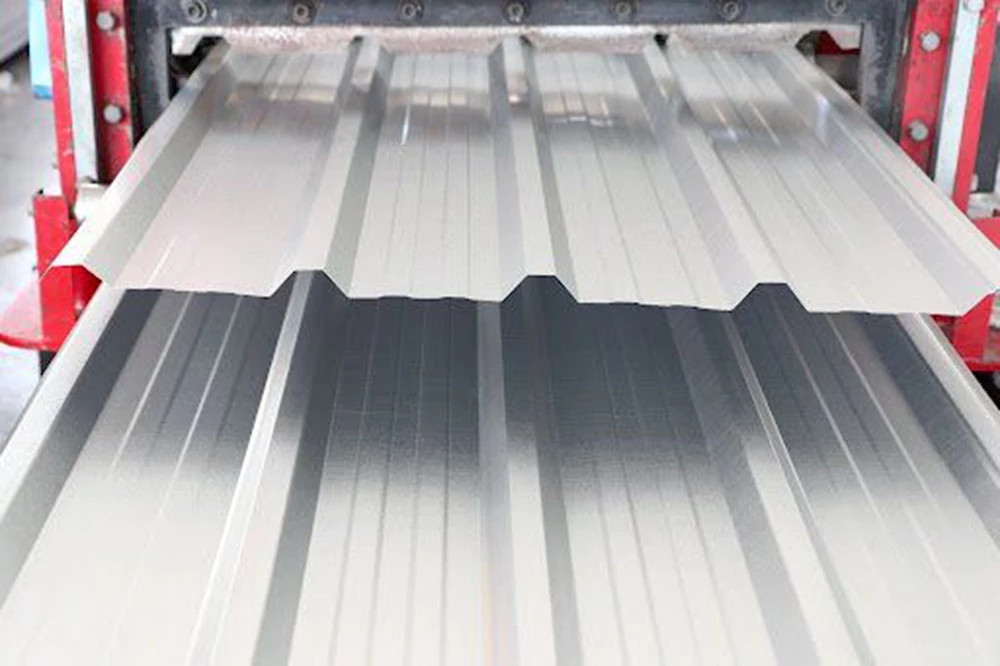

5. Galvanized Steel – Steel coated with zinc to prevent rusting. Used for metal roofing, appliances, nails, screws etc.

What is the Advantage of Sheet Metal?

There are several beneficial properties making sheet metal a preferred choice:

Lightweight Strength

Sheet metal provides an excellent strength-to-weight ratio. It is far stronger compared to plastics and wood materials of the same weight. This enables building lightweight structures leading to material savings and fuel efficiency.

Formability

The thin sheets allow bending and forming using metal fabrication techniques like stamping, pressing, rolling and die casting. This high formability produces custom cross-sections not easily possible with metal blocks.

Corrosion Resistance

Metals like stainless steel and aluminum provide excellent corrosion resistance and weatherability. This leads to low maintenance requirements and long working life in harsh operating environments.

Conductivity

Metals are naturally good conductors of heat and electricity. Copper and aluminum sheet metal are hence vital for heating elements, heat exchangers and electrical shielding needs.

Aesthetic Appeal

The smooth surfaces of sheet metal make them easy to paint or decorate compared to casted parts. This allows visual branding and appeal in consumer products.

Recyclability

Sheet metals retain properties despite repeated recycling. This makes steel, aluminum and copper sheets environmentally sustainable materials for circular supply chains.

What Uses Sheet Metal?

Due to the above characteristics, applications of sheet metal include:

Building and Construction: Roofing and flashing, wall cladding, ducts and vents

Appliances: Washing machines, refrigerators, ovens etc.

Automobile and Aerospace: Vehicle body panels, aircraft skin

Electronics: Shielding, casings, heat sinks

Materials Handling: Conveyors, trailers, catwalks

Signage: Logos, letters for branding and wayfinding

Furniture: Lockers, carts and storage solutions

How Thick is Sheet Metal?

As per industry standards, sheet metal ranges from 0.5mm to 6mm in thickness.

The common gauges are:

Light Gauge – 0.5mm to 1mm

Used where light weight and formability is important such as electronics enclosures

Medium Gauge – 1mm to 3mm

Provides good structural strength. Used for low-stress vehicle body panels.

Heavy Gauge – 3mm to 6mm

Very high strength but is harder to fabricate. Used where durability is critical such as heavy machinery parts.

However, thinner and thicker gauges outside these standard ranges can also be customized as per application requirements.

Factors that determine appropriate sheet metal thickness include:

– Strength needs

– Tolerable fabrication complexity

– Weight restrictions

– Cost considerations

– Corrosion resistance needs

By balancing these aspects, suitable sheet metal gauges can be selected for niche low or high thickness requirements.

How to Find Sheet Metal Fabrication Near Me?

To locate sheet metal manufacturing services nearby:

●Search online directories like Google Maps and Yellow Pages for “Sheet Metal Fabricator”

●Check manufacturer association listings in your country like the Fabricators & Manufacturers Association

●Seek referrals from architect and contractor networks

●Evaluate online sheet metal fabricators delivering nationwide

●Compare capabilities, pricing models and lead times before selection

Conclusion

Sheet metal offers the combined advantages of strength, durability, lightweight versatility and formability making it indispensable across domains.

Understanding sheet metal types and uses empower you to leverage such fabrication for your application needs.

Partnering with qualified local or online sheet metal shops assists in materializing projects as per engineering specifications.

Sheet metal refers to metal that has been formed into thin, flat pieces or sheets. The thickness of sheet metal is 0.5mm to 6mm. So it is much thinner than a metal block or bar. Sheet metal maintains uniform thickness along with mechanical strength after the fabrication process like bending or deep drawing.

Sheet metal is a broad term for metal formed into thin flat pieces whereas steel refers to a specific metal alloy with high iron content. So all steel when made into sheets is a type of sheet metal. However, not all metals used for sheet fabrication are steel. Other alloys like aluminum and copper are also popularly deployed for specialized sheet metal applications.

- Lightweight Strength

- Formability

- Corrosion Resistance

- Conductivity

- Aesthetic Appeal

- Recyclability