Printed Circuit Boards (PCBs) are integral components of modern electronic devices, serving as the foundational backbone for connecting electronic components and ensuring their proper functionality. For manufacturers and designers, producing high-quality PCBs involves several critical steps, including design, prototyping, and assembly. Among these, PCB assembly is a crucial phase where the actual electronic components are mounted and connected on the board. This is where turnkey PCB assembly services come into play, offering a comprehensive solution that simplifies the process and streamlines production.

What is Turnkey PCB Assembly?

Turnkey PCB assembly refers to a comprehensive service offered by specialized companies that manage the entire PCB assembly process from start to finish. The term “turnkey” signifies that the service provider delivers a complete solution, meaning the customer hands over the project with a design in hand and receives a fully assembled, tested, and ready-to-use PCB at the end. This approach contrasts with traditional methods where the customer might need to coordinate multiple vendors for different stages of the process.

What are the benefits of turnkey PCB assembly?

Opting for turnkey PCB assembly services offers numerous advantages:

1. Simplified Process: By handling all aspects of PCB assembly, turnkey services eliminate the need for customers to coordinate between multiple vendors, reducing complexity and potential miscommunications.

2. Cost Efficiency: Turnkey providers often benefit from bulk purchasing and established supplier relationships, which can translate to cost savings on components and materials. Additionally, the streamlined process reduces labor costs and potential errors, further driving down overall costs.

3. Time Savings: The end-to-end service model accelerates the production timeline. Customers can benefit from reduced lead times and quicker turnaround, which is crucial for fast-paced industries and time-sensitive projects.

4. Quality Assurance: Turnkey PCB assembly providers typically employ stringent quality control measures throughout the process. This ensures that the final product meets high standards of performance and reliability, minimizing the risk of defects and failures.

5. Technical Expertise: Specialized turnkey services bring a wealth of experience and technical knowledge to the table. Their expertise can be invaluable in optimizing designs, selecting appropriate components, and resolving any issues that arise during assembly.

6. Scalability: Turnkey PCB assembly services are well-equipped to handle projects of varying scales, from small prototype runs to large-scale production. This flexibility makes them suitable for a wide range of applications and industries.

What’s the turnkey PCB assembly process?

The turnkey PCB assembly process typically involves several key stages:

1. Design Review and Feasibility Analysis: The process begins with a thorough review of the PCB design files provided by the customer. This stage includes assessing the design for manufacturability, identifying potential issues, and ensuring that the design meets all necessary specifications and industry standards.

2. Component Sourcing: Once the design is finalized, the next step involves sourcing the components required for assembly. Turnkey PCB assembly services manage this task by procuring all necessary components, often leveraging their established relationships with component suppliers to obtain high-quality parts at competitive prices.

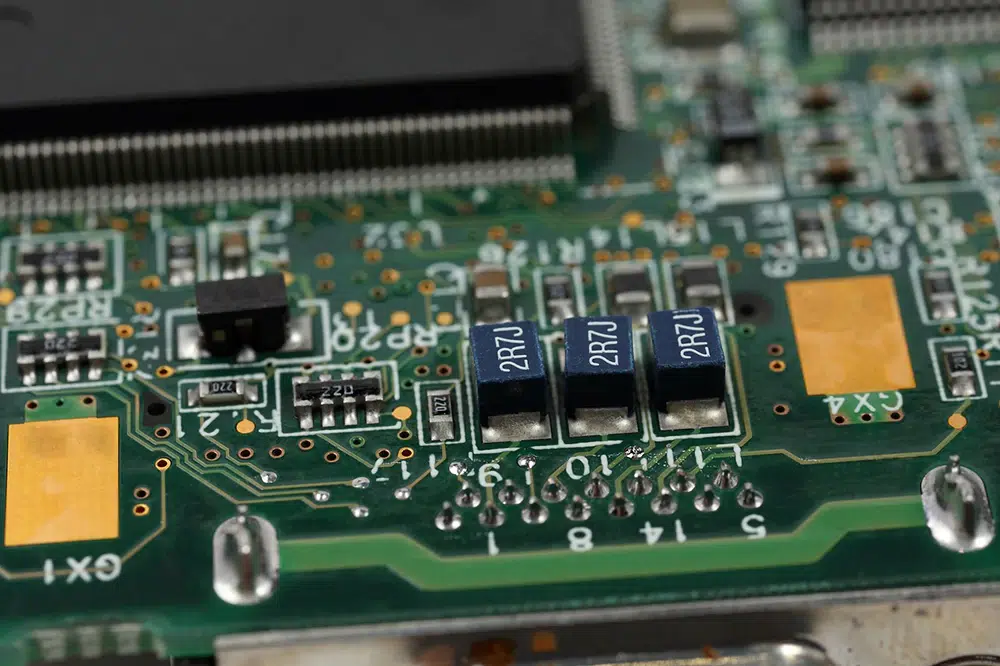

3. PCB Fabrication: With components in hand, the next step is the fabrication of the PCB itself. This involves creating the physical board, which includes etching the circuit patterns, drilling holes for component leads, and applying solder masks and silkscreen layers.

4. Assembly: The actual assembly process follows, where components are placed onto the PCB. This can be done through various methods, including Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT is often preferred for its precision and efficiency in mounting smaller components, while THT is used for larger components or where mechanical strength is required.

5. Soldering: After components are placed, they need to be soldered to the board to ensure electrical connectivity. This can be achieved through reflow soldering (for SMT components) or wave soldering (for THT components).

6. Testing and Quality Assurance: Post-assembly, the PCBs undergo rigorous testing to ensure they function correctly and meet quality standards. This can include functional testing, electrical testing, and visual inspections to detect any defects or issues.

7. Packaging and Delivery: Finally, the assembled and tested PCBs are packaged and shipped to the customer. Turnkey services often provide additional options for custom packaging and shipping arrangements to meet specific customer needs.

How to choose a turnkey PCB assembly provider?

When selecting a turnkey PCB assembly provider, several factors should be considered:

1. Experience and Expertise: Look for providers with a proven track record in your specific industry and application. Their experience will be instrumental in navigating any challenges and ensuring a successful outcome.

2. Capabilities and Equipment: Ensure the provider has the necessary equipment and capabilities to handle your project requirements, including advanced assembly technologies and quality control processes.

3. Cost and Lead Time: Evaluate the provider’s pricing structure and lead times to ensure they align with your budget and project timeline. While cost is important, it should not compromise quality and reliability.

4. Customer Support: Good customer support is crucial for addressing any issues or concerns that may arise during the assembly process. Choose a provider that offers responsive and effective support throughout the project.

5.Reputation and Reviews: Research the provider’s reputation and seek reviews or testimonials from previous customers. Positive feedback and a strong reputation are indicators of a reliable and trustworthy service.

which company can provide turnkey PCB assembly service?

1. PCBGOGO

https://www.pcbgogo.com

2. PCBWay

https://www.pcbway.com

3. Technotronix

https://www.technotronix.us

4. 7pcb.com

https://www.7pcb.com

5. Rush PCB

https://rushpcb.com

6. Mermar Electronics

https://mermarinc.com

7. NextPCB

https://www.nextpcb.com

8. FX PCB

https://sfxpcb.com

9. IBE

https://www.pcbaaa.com/

10. XPCB LIMITED

https://www.x-pcb.com

Conclusion

Turnkey PCB assembly represents a holistic approach to PCB manufacturing, offering a streamlined and efficient solution for producing high-quality printed circuit boards. By managing every aspect of the assembly process—from design review and component sourcing to testing and delivery—turnkey services simplify the production workflow, reduce costs, and enhance overall product quality. As electronic devices continue to evolve and become more complex, turnkey PCB assembly services provide a valuable resource for manufacturers and designers seeking to bring their innovative ideas to market efficiently and effectively.

Turnkey PCB assembly refers to a comprehensive service offered by specialized companies that manage the entire PCB assembly process from start to finish.

1. Design Review and Feasibility Analysis

2. Component Sourcing

3. PCB Fabrication

4. Assembly

5. Soldering

6. Testing and Quality Assurance

7. Packaging and Delivery

1. Simplified Process

2. Cost Efficiency

3. Time Savings

4. Quality Assurance

5. Technical Expertise

6. Scalability