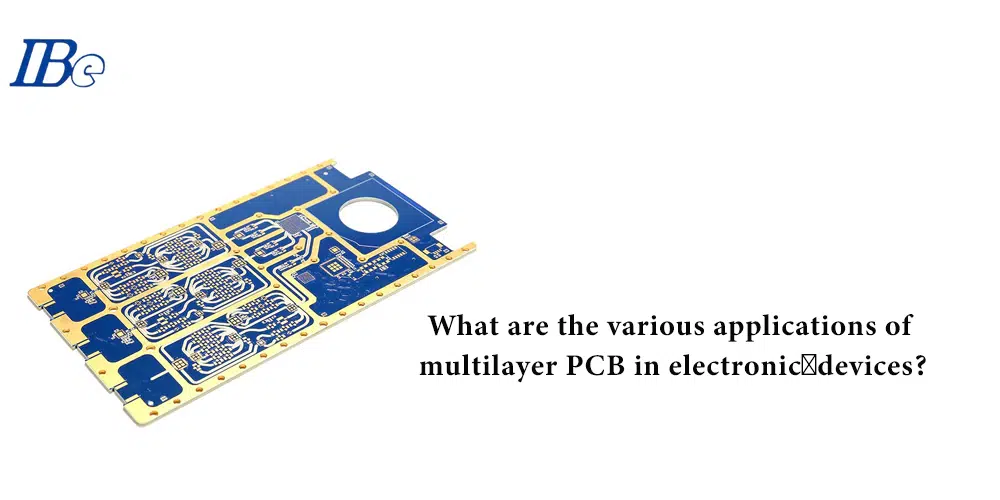

Multilayer PCB, one of the PCB types, can be easily found in various electronic devices. Multilayer PCB (Printed Circuit Board) is an electronic component with multiple conductive layers, which is widely used in various electronic devices. In this article, we will learn deeply about multilayer PCB’s strength, its applications in electronics, and its manufacturing difficulties and solution.

What are the strengths of multilayer PCB?

1. Higher level of integration

The multilayer PCB board adopts a layered design. Multiple functional modules can be distributed on different layers, thereby achieving a higher degree of integration. This can not only reduce the number of components and cost, but also improve the stability and reliability of the system.

2. Smaller size

Compared with single-layer PCB boards, multilayer PCB boards can achieve larger line widths, thereby reducing the size of the entire circuit board. This is especially important for electronic devices that require a large number of components to fit in a limited space, such as mobile phones, tablets, etc.

3. Lower electromagnetic interference

Multilayer PCB can reduce electromagnetic interference through physical isolation. For example, a layer of insulating material can be added between different layers to prevent signals from interfering with each other. In addition, multilayer PCB boards can also use technologies such as shielding layers and ground wires to further reduce electromagnetic interference.

What are the various applications of multilayer PCB in electronic devices?

1. High-performance computing field

In the field of high-performance computing, multilayer PCB boards can achieve higher integration and lower power consumption, thereby improving computing performance and operating efficiency. For example, in supercomputers, servers and other equipment, multilayer PCB circuit boards are widely used.

2. Automotive electronics field

With the continuous improvement of the electronic degree of automobiles, the demand for multilayer PCB circuit boards is also increasing. For example, in equipment such as car navigation systems and vehicle communication systems, multilayer PCB can achieve more efficient data transmission and processing capabilities.

3. IoT field

The popularity and development of Internet of Things devices put forward higher requirements for multilayer PCB. For example, in smart home, industrial automation and other equipment, multilayer PCB can achieve more complex functions and higher reliability.

With the development of science and technology, multilayer PCB circuit boards are more and more widely used in electronic equipment. With its advantages of high integration, small size and low electromagnetic interference, it provides strong technical support for various electronic devices. In the future, multilayer PCB will continue to exert their great potential and promote the continuous advancement of electronic technology.

With the development of science and technology, multilayer PCB circuit boards are more and more widely used in electronic equipment. With its advantages of high integration, small size and low electromagnetic interference, it provides strong technical support for various electronic devices. In the future, multilayer PCB will continue to exert their great potential and promote the continuous advancement of electronic technology.

Difficulties and solutions in the manufacture of multilayer PCB

Manufacturing multilayer PCB circuit boards is a complex process involving many technical difficulties.

First of all, the quality and thickness of materials need to be precisely controlled during the manufacturing process of multilayer PCB. Due to differences in electrical conductivity and thermal resistance between different layers, it is necessary to select appropriate materials to meet specific requirements during the fabrication process. In addition, the thickness of the material needs to be accurately measured to ensure consistent electrical conductivity from layer to layer. This is critical to improving the overall performance and reliability of the board.

Secondly, the problem of signal transmission needs to be solved in the manufacturing process of multilayer PCB. Since signal paths in a multilayer PCB can be affected by interlayer interference, measures need to be taken to reduce this interference. A common solution is to use high-speed differential signal lines or metal grid structures to improve signal transmission quality and anti-interference capabilities.

In addition, the optimization of layout and wiring needs to be paid attention to during the manufacturing process of multilayer PCB. Reasonable layout can reduce signal delay, reduce electromagnetic interference, and improve the heat dissipation performance of the circuit board. In terms of wiring, certain rules and standards need to be followed, such as avoiding crossings between parallel lines, minimizing the length of adjacent lines, etc., to ensure good electrical connection and signal transmission quality.

Finally, environmental protection and sustainability issues also need to be paid attention to during the manufacturing process of multilayer PCB. With increasing awareness of environmental protection, manufacturers are increasingly focusing on efforts to reduce the use of chemicals, reduce waste generation, and adopt renewable energy sources. Therefore, environmentally friendly materials and technologies should be selected when manufacturing multilayer PCB , and effective waste disposal methods should be adopted.

To sum up, the manufacture of multilayer PCB circuit boards involves many technical difficulties and challenges. By studying these difficulties in depth and adopting corresponding solutions and techniques, the quality and performance of multilayer PCB circuit boards can be improved to meet the ever-increasing demand for electronic equipment.