In the realm of modern electronics manufacturing, three key technologies play pivotal roles in determining how components are mounted onto printed circuit boards (PCBs) and assembled into functional devices: Surface Mount Devices (SMD), Surface Mount Technology (SMT), and Through-Hole Technology (THT). Each of these technologies offers distinct advantages and is employed based on specific design requirements, production volumes, and cost considerations.

The terms SMD, SMT, and THT are related to different methods of mounting electronic components onto printed circuit boards (PCBs):

1. SMD (Surface Mount Device):

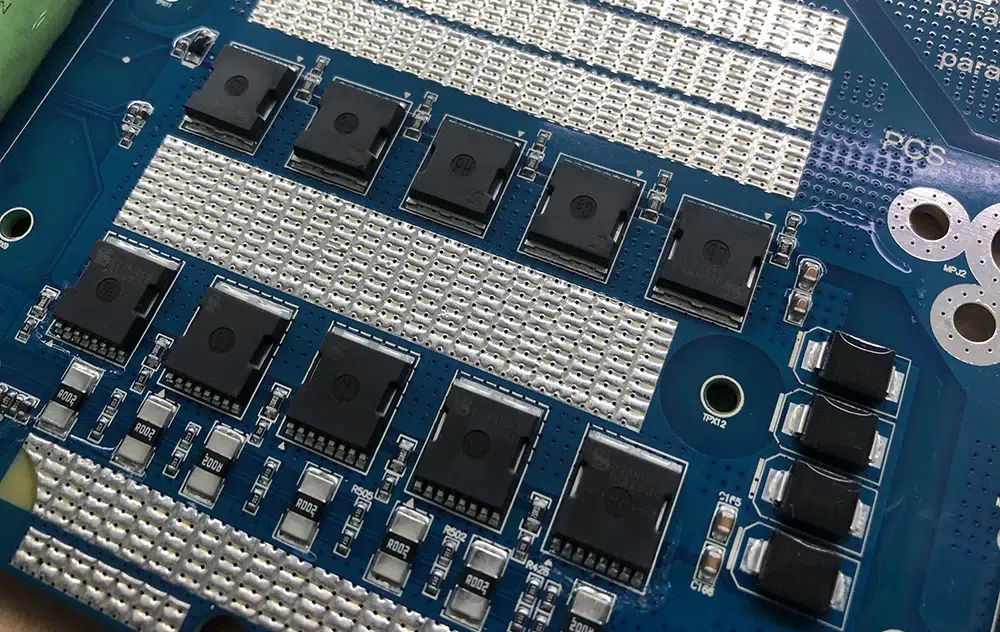

– Definition: SMD refer to electronic components that are designed to be mounted directly onto the surface of a PCB. These components do not have leads or pins that go through holes in the board like traditional Through-Hole Technology (THT) components. Instead, they have small metalized terminals or pads that can be soldered directly onto the PCB surface.

– Mounting: These components have small, flat contacts (pads) that are soldered directly onto the PCB pads using solder paste and a reflow soldering process.

– Advantages: SMD components are smaller, lighter, and generally allow for higher component density on PCBs. They also facilitate automated assembly processes.

– Types of SMD Components:

Resistors and Capacitors: Surface mount resistors (SMD resistors) and surface mount capacitors (SMD capacitors) are among the most common SMD components used in electronics. They come in various sizes (e.g., 0402, 0603, 0805) indicating their dimensions in imperial units (inches).

Integrated Circuits (ICs): Many modern ICs are designed with SMD packages such as Quad Flat Package (QFP), Ball Grid Array (BGA), and Small Outline Integrated Circuit (SOIC), offering enhanced performance and heat dissipation.

Diodes and Transistors: SMD diodes and SMD transistors are crucial for power management, signal processing, and amplification in electronic circuits.

– Advantages of SMD:

Miniaturization: SMD components are typically smaller and lighter than their THT counterparts, allowing for more compact and lightweight electronic devices.

High-Density Integration: SMD technology enables higher component density on PCBs, facilitating the design of complex circuits in limited space.

Improved Electrical Performance: SMD components offer shorter interconnection paths, reducing parasitic inductance and capacitance, which can improve high-frequency performance.

Automated Assembly: SMD components are ideally suited for automated assembly processes such as pick-and-place machines, which significantly enhance manufacturing efficiency and reduce labor costs.

2. SMT (Surface Mount Technology):

– Definition: SMT is the overall process and technology used to mount SMD components onto a PCB. SMT encompasses the entire process of mounting SMD components onto PCBs. It includes the equipment, techniques, and materials used to achieve reliable solder connections between SMD components and PCBs. SMT has become the dominant method for PCB assembly in modern electronics manufacturing due to its efficiency and flexibility.

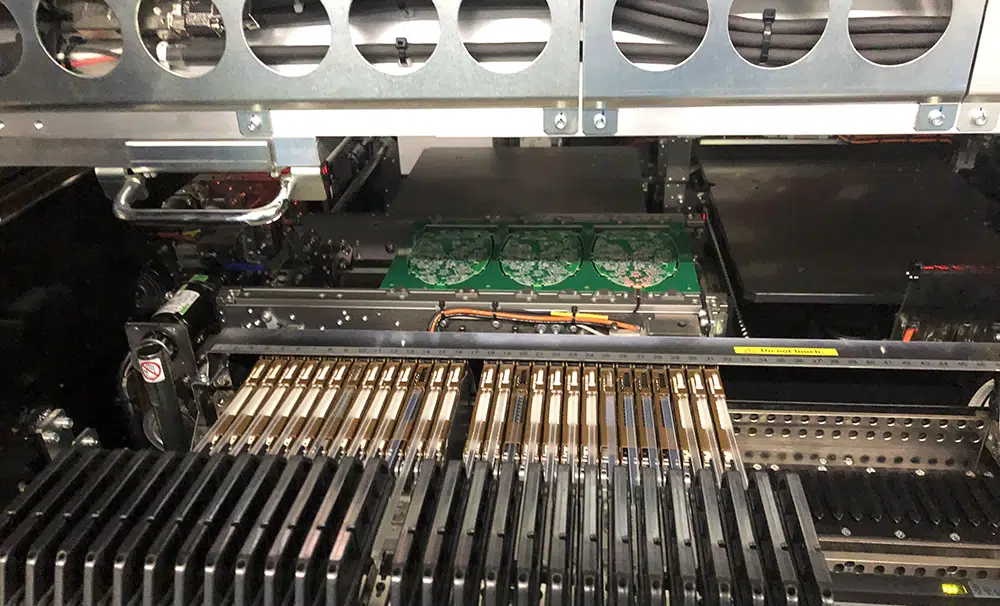

– Process: It involves applying solder paste onto the PCB pads, placing the SMD components onto the solder paste using pick-and-place machines, and then heating the assembly in a reflow oven to melt the solder and create electrical connections.

– Advantages: SMT enables faster assembly times, higher precision in component placement, and allows for smaller PCB designs compared to through-hole technology.

– Key Components of SMT:

Pick-and-Place Machines: Automated pick-and-place machines precisely position SMD components onto PCBs based on assembly instructions provided by CAD software.

Reflow Soldering: In reflow soldering, solder paste—a mixture of solder alloy particles and flux—is applied to the PCB pads. Components are then placed on the solder paste and subjected to controlled heating in a reflow oven, where the solder paste melts and forms reliable solder joints.

Stencil Printing: Stencil printing is used to deposit precise amounts of solder paste onto PCB pads. It ensures uniform solder deposits, critical for achieving reliable electrical connections during reflow soldering.

– Advantages of SMT:

Higher Production Throughput: SMT allows for faster assembly speeds and higher production volumes compared to THT, making it suitable for mass production of consumer electronics and industrial equipment.

Cost Efficiency: Automated SMT processes reduce labor costs and minimize material waste, contributing to overall cost efficiency in electronics manufacturing.

Design Flexibility: SMT supports the integration of advanced components and complex PCB designs, facilitating innovations in product functionality and performance.

3. THT (Through-Hole Technology):

– Definition: THT involves mounting components with wire leads or pins that pass through holes drilled in the PCB. These components are then soldered to pads or traces on the opposite side of the PCB, forming a mechanical and electrical connection.

– Mounting: Components are manually or automatically inserted through holes drilled in the PCB, and then soldered either by hand (soldering iron) or wave soldering (for mass production).

– Advantages: THT components offer strong mechanical bonds and can withstand mechanical stress better than SMD components. They are also easier to repair or replace.

– Applications of THT:

Power Electronics: THT components such as transformers, relays, and large capacitors are commonly used in power supplies, inverters, and industrial equipment where high current handling capability is required.

Prototyping: THT is preferred during initial prototyping stages where design changes and component substitutions are more frequent.

Mixed Technology: Some PCB assemblies incorporate both SMT and THT components, leveraging the strengths of each technology to optimize performance and manufacturing efficiency.

– Advantages of THT:

Mechanical Strength: THT components offer robust mechanical anchoring to the PCB, making them suitable for applications requiring durability and reliability under harsh environmental conditions.

Repair and Rework: THT components are easier to remove and replace manually, facilitating repair and rework processes during prototyping or maintenance.

Heat Dissipation: THT components often have larger leads or pins that can conduct heat away from the component body, enhancing thermal management capabilities in power electronics.

Key Differences:

– Mounting Method: SMD components are mounted directly onto the surface of the PCB, while THT components are mounted through holes drilled in the PCB.

– Size and Density: SMD components are generally smaller and allow for higher component density compared to THT components.

– Assembly Process: SMT involves the entire process of surface mounting, including solder paste application, component placement, and reflow soldering. THT involves components with leads that pass through the PCB and are soldered on the opposite side.

In summary, SMD and SMT are closely related, with SMD being the type of components and SMT describing the process of assembling those components onto PCBs. THT, on the other hand, represents an older method where components are mounted through holes in the PCB rather than on the surface.

While SMD and SMT dominate the production of modern electronics due to their efficiency, miniaturization capabilities, and high-density integration, Through-Hole Technology (THT) remains indispensable for applications requiring mechanical robustness, heat dissipation, and ease of repair.