The electronic manufacturing industry encompasses a wide range of products and fields, including electronic materials such as monocrystalline silicon, polycrystalline silicon, semiconductor discrete devices, integrated circuits, etc.; manufacturing of electronic components and equipment such as discrete devices, integrated circuits, capacitors, resistors, inductors, display devices, lithium batteries, connectors, electro-acoustic devices, etc.; consumer and industrial products such as mobile phones, microcomputers, tablet computers, communication equipment, etc.

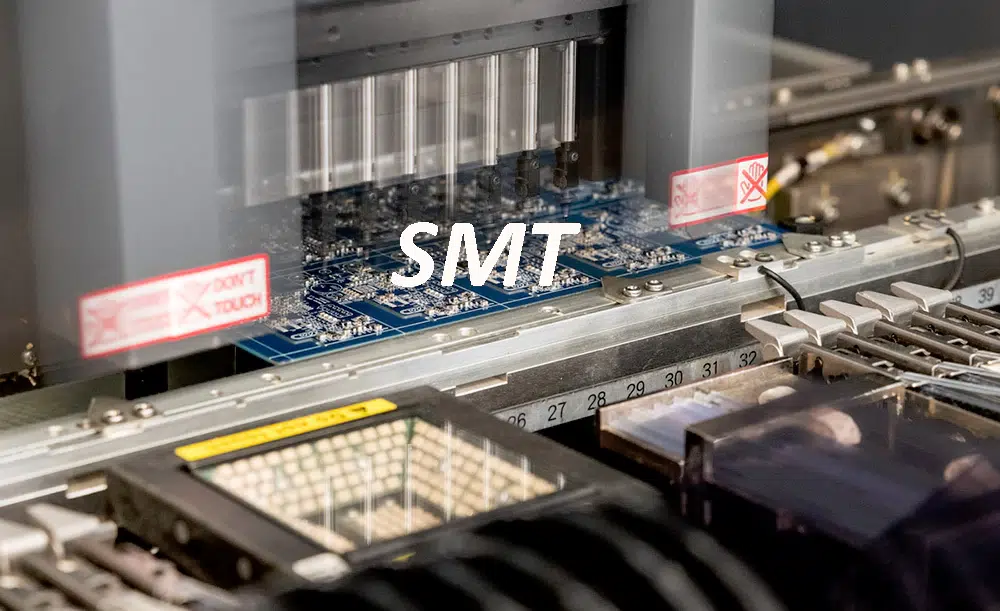

1. SMT (Surface Mount Technology)

– Surface Mount Technology, a manufacturing process where electronic components are directly mounted onto the surface of a printed circuit board (PCB).

2. PCB (Printed Circuit Board)

– Printed Circuit Board, used to support and connect electronic components in circuits.

3. DIP (Dual In-line Package)

– Dual In-line Package, a common form of electronic component packaging.

4. SMD (Surface Mount Device)

– Surface Mount Device, electronic components suitable for SMT processes.

5. BGA (Ball Grid Array)

– Ball Grid Array, a high-density packaging technology.

6. IC (Integrated Circuit)

– Integrated Circuit, a device that integrates multiple electronic components onto a single chip.

7. PCB Assembly

– The process of assembling electronic components onto a PCB.

8. Reflow Soldering

– A soldering process where components are soldered to a PCB by melting solder paste through heating.

9. AOI (Automated Optical Inspection)

– Automated Optical Inspection, used to inspect the quality of electronic components and solder joints on PCBs.

10. X-Ray Inspection

– X-Ray Inspection, used to inspect the quality of internal solder joints, such as those in BGA packages.

11. ICT (In-Circuit Test)

– In-Circuit Test, a functional test of electronic components on a PCB.

12. FCT (Functional Test)

– Functional Test, a test of the overall functionality of a PCB or product.

13. THT (Through Hole Technology)

– Through Hole Technology, a process of soldering electronic component leads through holes in a PCB.

14. SMT Line

– SMT Production Line, including equipment such as printers, pick-and-place machines, and reflow ovens used for SMT processes.

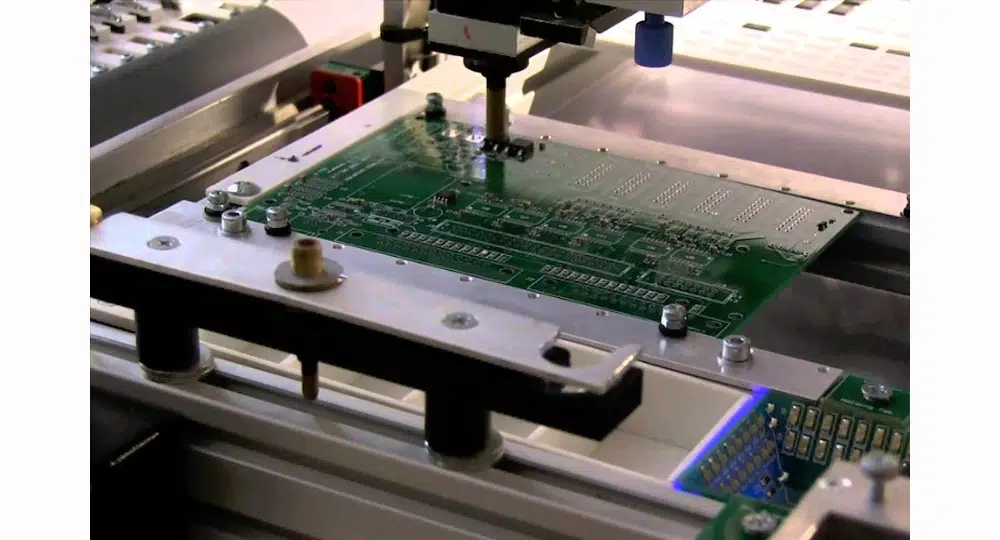

15. Component Mounting

– The process of accurately placing SMD components onto a PCB.

16. Stencil Printing

– Printing solder paste onto a PCB using a stencil.

17. Pick and Place

– Placing SMD components onto a PCB using a pick-and-place machine.

18. Solder Paste

– A mixture of metal powder and flux used to solder SMD components.

19. Lead-Free Solder

– Solder material that does not contain lead, used for environmental reasons.

20. Wave Soldering

– A method of soldering through-hole components on a PCB by passing them over a wave of molten solder.

21. Cleaning

– Removing contaminants and flux residues from a PCB.

22. Quality Control

– Ensuring products meet specified quality standards.

23. Yield

– The ratio of acceptable products to total production.

24. ESD (Electrostatic Discharge)

– Electrostatic discharge, a potential source of damage to electronic components.

25. Reliability

– The ability of a product to perform as intended under specified conditions.

26. PCB Fabrication

– The process of manufacturing PCBs, including design, drilling, etching, etc.

27. Component Lead Forming

– Shaping component leads for soldering or installation.

28. Solder Joint

– The connection point between an electronic component and a PCB.

29. Void

– A bubble or gap within a solder joint that may affect its quality and reliability.

30. PCB Thickness

– The thickness dimension of a PCB board.

31. Copper Thickness

– The thickness of copper foil on a PCB.

32. Impedance Control

– Ensuring signal transmission impedance matches on a PCB.

33. RF PCB

– RF PCB, used for high-frequency signal transmission.

34. Microvia

– Small diameter holes in a PCB.

35. Blind Via

– A hole that connects internal layers of a PCB but does not go through the entire board.

36. Buried Via

– A hole that is completely enclosed within inner layers of a PCB.

37. PCB Material

– Materials used for PCBs, such as FR-4, Rogers, etc.

38. SMT Component Feeder

– Device supplying SMD components to pick-and-place machines.

39. Nozzle

– Pick-and-place machine tool used for picking up and placing SMD components.

40. Feeder Calibration

– Calibration of SMD component feeders to ensure accurate component supply.

41. Component Placement Accuracy

– Precision in placing components by pick-and-place machines.

42. Reflow Profile

– Temperature profile in a reflow oven that affects soldering quality.

43. Solderability

– The ability of electronic component pins or PCB pads to be soldered.

44. PCB Flux

– Chemical substance used to facilitate soldering.

45. Solder Spatter

– Splattering of solder particles during soldering.

46. Tombstoning

– Vertical standing of SMD components due to uneven soldering.

47. Component Shift

– Deviation of component position after placement compared to design.

48. PCB Warpage

– Bending or deformation of a PCB.

49. SMT Production Line

– Overall process flow of SMT production, including printing, component placement, reflow soldering, etc.

50. Cycle Time

– Time required to complete one production cycle.

51. SMT Stencil

– Stencil used for printing solder paste in SMT.

52. Adhesive

– Material used to secure SMD components on a PCB.

53. Component Packaging

– The appearance and pin arrangement of electronic components.

54. QFN (Quad Flat No-Lead)

– Surface mount package with no leads on its sides.

55. SOP (Small Outline Package)

– Common type of integrated circuit package.

56. SOJ (Small Outline J-lead Package)

– Small outline package with J-shaped leads.

57. PLCC (Plastic Leaded Chip Carrier)

– Plastic package for integrated circuits.

58. PGA (Pin Grid Array)

– Package with pins arranged in a grid pattern.

59. COB (Chip-on-Board)

– Mounting method where chips are directly mounted on a PCB.

60. Wire Bonding

– Method of connecting chips to a PCB or substrate.

61. Flip Chip

– Chip mounted face-down on a PCB or substrate.

62. Underfill

– Material used to fill the gap between a chip and PCB for enhanced reliability.

63. PCB Design

– Includes layout, routing, signal integrity considerations, etc.

64. Gerber File

– Graphic file format used for PCB manufacturing.

65. DFM (Design for Manufacturing)

– PCB design method considering manufacturing processes.

66. NPI (New Product Introduction)

– Process of introducing a new product into production.

67. BOM (Bill of Materials)

– List of materials needed for production.

68. MOQ (Minimum Order Quantity)

– Minimum quantity suppliers require for orders.

69. JIT (Just-in-Time)

– Production method where parts are produced as needed.

70. Kanban

– Signal system for controlling production flow.

71. Cost of Goods Sold

– Direct costs incurred in producing goods.

72. ROI (Return on Investment)

– Measure of investment profitability.

73. ERP (Enterprise Resource Planning)

– Integrated management system for business processes.

74. MES (Manufacturing Execution System)

– Real-time monitoring and management of production processes.

75. Six Sigma

– Quality management method aiming to reduce defects and improve process stability.

More electronic terms/terminologies will be updated…