PCBs form the backbone of electronics, providing the foundation upon which components are mounted and connected in almost every electronic product and system.

For rapid prototyping, custom tools, and small production runs, manufacturing PCBs yourself has tremendous advantages over outsourcing fabrication. With the emergence of compact, desktop PCB printers, printing circuit boards in-house is now accessible and practical even for individual inventors, startups, and makers.

This comprehensive guide covers everything you need to know about PCB printing materials, equipment, processes, and costs to start printing your own high-quality PCBs.

How Do I Print a PCB?

PCB Printing requires a specialized PCB printer, blank PCB substrate, electronic design files, and printed circuit board software to control the printer.

First, the circuit layout must be designed in EDA software and exported to standard gerber and drill file formats compatible with PCB printers.

The blank PCB substrate is loaded into the printer, which can be an affordable desktop printer like the Voltera V-One or an industrial machine like the LPKF ProtoMat.

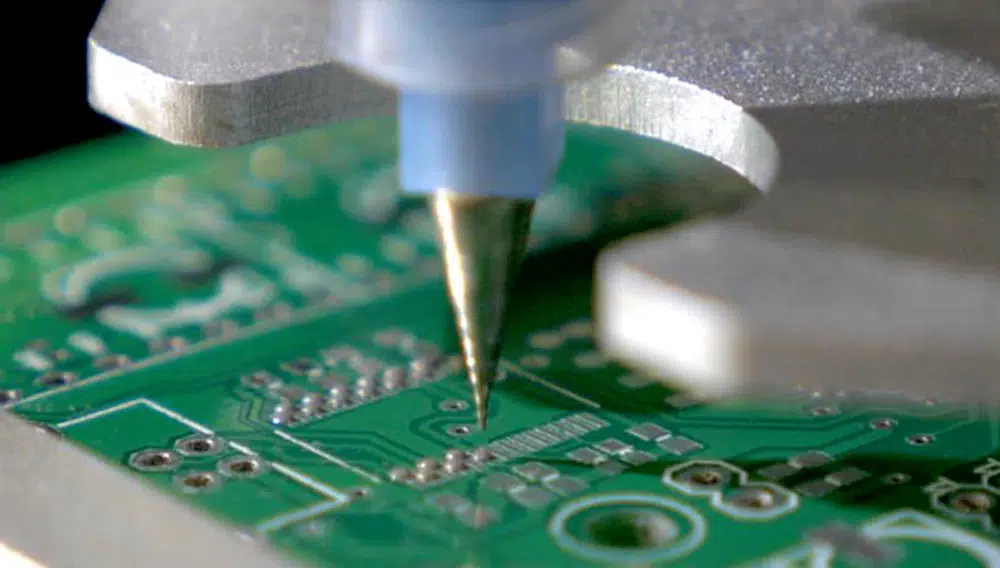

The print software then interprets the gerber files, communicating the circuit layer images to the printer to deposit conductive inks precisely onto the blank PCB substrate.

After printing, curing and etching processes complete the PCB fabrication. The final result is a custom printed circuit board ready for electronics assembly.

What is a PCB Printing Machine?

A PCB printing is a device designed specifically for printing the circuits and traces onto blank PCB boards. These printers work similarly to inkjet document printers, but instead of depositing ink onto paper, they deposit conductive inks, like copper, onto the PCB substrate.

PCB printers are highly specialized devices optimized for printing intricate circuit patterns with precision and high resolution. They allow printing multi-layer boards with fine features down to 100 microns or lower.

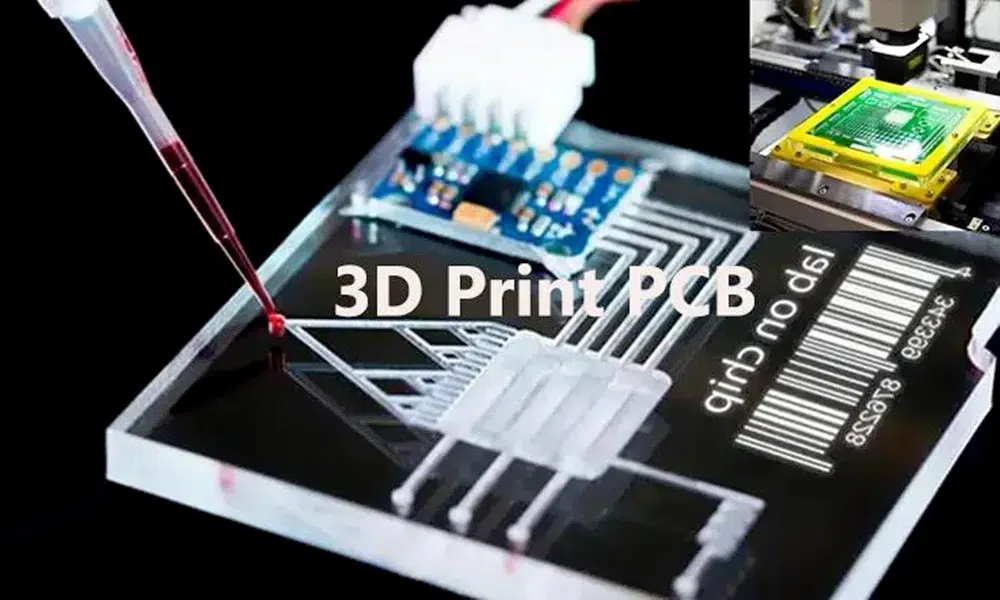

Can I 3D Print a PCB?

While it may seem possible to 3D print conductive traces using conductive filaments, 3D printing cannot achieve the fine resolution and layered printing needed for functional printed circuit boards. 3D printing builds objects in three dimensions, while PCB printing requires precise two-dimensional tracing deposited onto the substrate.

So 3D printing currently lacks both the resolution and layered printing capability to produce working boards. However, it can be useful for printing enclosures and mechanical structures for PCB projects.

Which Paper is Used for PCB Printing?

PCBs are not printed onto paper. Blank PCB substrates are fiberglass boards pre-coated with a thin copper layer onto which the desired circuit layout will be printed. FR-4 glass epoxy and CEM-1 composites are common PCB substrate materials.

Once the board has been printed, it goes through an etching process to remove unwanted copper, leaving only the printed traces on the board. The PCB can then be populated with electronic components to build the circuit.

What PCB Printer Should I Use?

There are several PCB printer models available for small production or hobbyist use. Top options include:

Voltera V-One: Compact desktop PCB printer for prototyping. Prints single or double-sided boards up to a max size of 100mm x 150mm. Costs around $3,499.

Nano Dimension Dragonfly: High-precision 3D printer that also prints functional multilayer PCBs. Costs over $100,000 new.

LPKF ProtoMat E33: Widely used small-format PCB printer. Prints boards up to 220 mm x 305mm size. New units cost over $15,000.

For hobbyists, the Voltera V-One provides an affordable entry point for small-scale PCB printing. LPKF and Nano Dimension machines offer much higher production capability for professional applications.

What is the PCB Printing Process?

Printing PCBs involves careful preparation in design software before sending the board image file to the printer. Here is an overview of the complete PCB printing workflow:

1. Design Circuit Board: Create the PCB design in EDA software like Eagle, KiCad or Altium. This includes laying out pads, traces, and circuit components.

2. Generate Print Files: Convert the PCB layout into Gerber and drill files compatible with the printer. This may require CAM software.

3. Prepare Printer: Set up and calibrate the PCB printer hardware and software. Load the blank PCB substrate.

4. Import Design Files: Import the Gerber files into the printer driver or software. Check designs.

5. Print Board: Carefully check printer settings, then print the design onto the blank PCB substrate.

6. Dry and Cure: Allow freshly printed boards to dry. Cure conductive ink traces in a reflow oven or Hot Air SMD station.

7. Etch Board: Etch away unwanted copper to isolate printed traces using a chemical etchant solution.

Once the PCB is fully etched and cured, electronic components can be soldered on to complete the circuit build.

How Much Does It Cost To Get A PCB Printed?

Printing costs depend on the PCB printer service or machine used. On the low end, hobbyist printers like the Voltera V-One can print boards for under $5 in materials. Small batches from commercial PCB printers typically start around $25-$50 per design iteration.

Economies of scale apply for bulk orders from fabrication shops. Simple single or double-sided boards can cost $5 each when ordering thousands of units. Complex boards with more layers and smaller features are more expensive. Rush processing, special materials, and stencils or testing further increase costs.

It’s recommended you get quotes from a few different vendors when considering production. Evaluate both local specialty printers and large volume manufacturers in Asia.

PCB Printing Near Me

For one-off prototyping, find a maker space, Fab Lab, or innovation hub near you. Many open community workshops have PCB printers available for public use.

Online services like 3DHubs and Radiant Manufacturing connect with local engineers and prototyping shops that offer PCB printing. Or use PCB fabrication marketplaces like IBE Electronics, PCBWay, ALLPCB or JLPCB to get quotes from vendors optimized for your country.

Conclusion

PCB Printing is now easier and more affordable than ever thanks to advancing home and professional grade printers. By understanding the PCB printing process, substrate materials, specialized equipment required, costs, and local access options, engineers can effectively produce professional quality printed circuit boards tailored to their electronics projects.

A PCB printing machine is a device designed specifically for printing circuits and traces onto blank PCB boards. These printers work similarly to inkjet document printers, but instead of depositing ink onto paper, they deposit conductive inks, like copper, onto the PCB substrate.

PCBs are not printed onto paper. Blank PCB substrates are fiberglass boards pre-coated with a thin copper layer onto which the desired circuit layout will be printed. FR-4 glass epoxy and CEM-1 composites are common PCB substrate materials.

1. Design Circuit Board

2. Generate Print Files

3. Prepare Printer

4. Import Design Files

5. Print Board

6. Dry and Cure

7. Etch Board