The integration of compact and technologically advanced components is pivotal for innovation and progress in the dynamic landscape of modern electronics and among these, Surface Mount Devices (SMD) stand out as the cornerstone of contemporary electronic manufacturing.

What does SMD stand for?

SMD stands for Surface Mount Device and comes with the electronic components, placed directly over the surface of the PCB (Printed Circuit Board). SMDs act differently from through-hole components as in the case of through-hole components, leads go into holes on the PCBs while soldering on the opposite side.

The transition from through-hole to surface mount technology has been a remarkable development in the electronics industry that offers numerous advantages in terms of space efficiency, manufacturing automation, and performance.

What is the meaning of SMD technology?

Surface Mount Device (SMD) technology is a process that helps in constructing electronic circuits where components are mounted directly onto the surface of PCBs. This approach eliminates the need for holes and leads, making it more space-efficient and allowing for automated assembly processes.

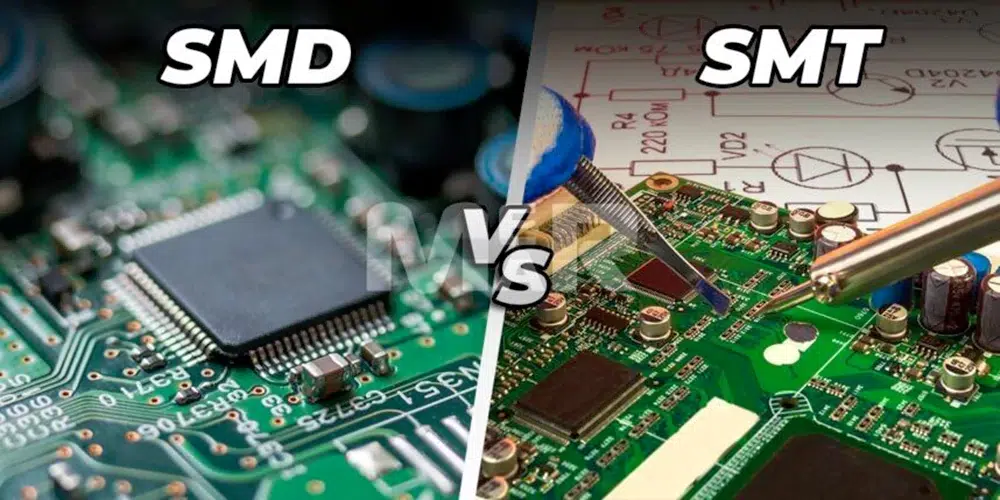

What is the difference between SMT and SMD?

SMT is a comprehensive method that surpasses SMDs, covering the entire surface mount assembly process. It includes placing, soldering, applying solder paste, utilizing pick-and-place machines, and employing reflow soldering on PCBs.

Conversely, SMD refers to individual electronic components designed for resistors, capacitors, and integrated circuits in surface mounting applications.

What are the different types of SMD?

SMD Resistors: These are surface mount resistors that come in various sizes as well as resistance values. SMD resistors are widely used in electronic circuits for controlling the flow of electric current.

SMD Capacitors: Similar to resistors, SMD capacitors are important for storing as well as releasing electrical energy. They are available in different capacitance values and voltage ratings.

SMD Diodes: These are pivotal semiconductor devices, that are indispensable for directing uni-directional current in circuits, particularly in applications like rectification as well as signal demodulation.

SMD Inductors: These inductors are adept at storing energy in magnetic fields during the flow of electric current, which serves as integral components in circuits providing power to devices and filtering signals.

SMD Transistors: These versatile semiconductor devices, excel in switching as well as amplifying electronic signals while acting as key players in applications ranging from amplifiers and oscillators to logic circuits.

SMD Integrated Circuits (ICs): These circuits are complex assemblies of multiple electronic components within a single package. SMD ICs can include microcontrollers, operational amplifiers, as well as digital signal processors.

What is an SMD LED?

SMD LEDs find extensive application in displays, indicator lights, and general lighting. SMD LEDs are known for their compact size, energy efficiency, and durability. They have largely replaced traditional through-hole LEDs in many applications due to their compatibility with automated assembly processes and their ability to provide higher resolution when it comes to displaying.

What is the SMD resistor code?

SMD resistors are commonly identified by a 3-4 digit alphanumeric code that specifies their resistance value. The resistor code typically follows the EIA-96 standard, where the first two digits represent the significant figures, and the third digit represents the multiplier. The fourth digit, if present, indicates the tolerance.

For example, an SMD resistor with the code “473” would have a resistance value of 47 x 10^3 ohms, or 47 kilohms, with a tolerance determined by the fourth digit if provided.

How to solder SMD?

Here’s a step-by-step guide on how to solder SMD components:

Prepare the Tools:

●Soldering iron with a fine tip

●Tweezers

●Solder wire (preferably with a small diameter)

●Flux (for improved solder flow)

Apply Flux:

When soldering, a slight flux application on the SMD pads of the PCB aids in the wetting and adhesion of the solder.

Place the Component:

Use tweezers to carefully place the SMD component on the designated pads while ensuring correct orientation as well as alignment.

Soldering:

Applying a modest amount of solder to the joint ensures a secure connection. For that, touch the soldering iron tip to both the component lead & the pad.

Inspect the Joint:

Once the soldering is done, inspect the joint carefully. Make sure to avoid excess soldering that may cause a short circuit.

Repeat for Other Components:

Repeat the procedure for other SMD components on the PCB.

Cleaning:

Clean the soldered joints with isopropyl alcohol to remove flux residues.

Reflow Soldering:

Reflow soldering is done through ovens or hot air rework stations that provide efficient means to solder multiple SMD components. This method is efficient for mass production.

Conclusion

The way we make electronics has seen a big change thanks to Surface Mount Device (SMD) technology. It brings more efficiency, smaller sizes, as well as better performance. Knowing about different SMD components like resistors, capacitors, LEDs, and integrated circuits is important when you’re putting together the electronic circuits we use today.

The transition from through-hole to surface mount technology has brought about significant advancements, with SMD components becoming ubiquitous in electronic devices we use daily.

If you love tinkering with electronics, enjoy it as a hobby, or work in the field professionally, having a good grasp of SMD technology and its components is a must. It helps you keep up with the constant changes in the exciting world of electronics.

SMD stands for Surface Mount Device and comes with the electronic components, placed directly over the surface of the PCB (Printed Circuit Board). SMDs act differently from through-hole components as in the case of through-hole components, leads go into holes on the PCBs while soldering on the opposite side.

SMT is a comprehensive method that surpasses SMDs, covering the entire surface mount assembly process. It includes placing, soldering, applying solder paste, utilizing pick-and-place machines, and employing reflow soldering on PCBs.

Conversely, SMD refers to individual electronic components designed for resistors, capacitors, and integrated circuits in surface mounting applications.

- SMD Resistors

- SMD Capacitors

- SMD Diodes

- SMD Inductors

- SMD Transistors

- SMD Integrated Circuits (ICs)