With the rapid development of technology, chips have become the core of modern electronic equipment. They not only control and operate various equipment, but also determine the performance and function of these equipment. This article will introduce you to the different types of chips, their characteristics and applications.

A semiconductor chip, also known as an integrated circuit or microprocessor, is a tiny electronic device that integrates a large number of electronic components (such as transistors, resistors, capacitors, etc.) on a small silicon chip. According to functions, uses, processes, principles, etc., the classification of chips can be described as diverse, varied, and messy. Today’s article will introduce the classification of chips:

Classified by function

According to the function, semiconductor chips are divided into five categories: logic chips, memory chips, sensor chips, power chips and communication chips. Each major category can be subdivided into several subcategories.

logic chip

Serial processing chip: CPU

Parallel processing chip: GPU

Programmable logic devices: FPGA, CPLD

Customized special purpose chip:ASIC

Including: PMU, NPU, DPU, MCU, etc.

Communication chip

Cellular communication chip: 2G, 3G, 4G, 5G

Near field communication chips: Bluetooth, WiFi, NFC, etc.

Satellite communication chip

Interface communication chip: HDMI, VGA, etc.

Sensor chip

Image sensor chip: CIS

Micro Electro Mechanical System Chip: MEMS

Touch chip, audio chip, GPS chip

chips, Hall sensor chips, etc.

Power chip

DCDC, ACDC power chip

LDO linear voltage regulator chip

power management chip

Memory chip

Flash:CPU

Read-only memory: ROM

Random access memory: SRAM, DRAM

Classified by working principle

According to the working principle, semiconductor chips can be divided into two categories: analog chips and digital chips.

Analog chips: Analog chips process natural analog signals such as continuous light, sound, speed, and temperature (including radio frequency chips, sensor chips, etc.). Generally, the process requirements for chips are not high (especially for high-power devices, sometimes the substrate is more expensive than the process), and more attention is paid to the characteristics of components such as reliability, stability, energy conversion efficiency, voltage and current control capabilities, etc.

Digital chip: The main function of digital chip is to realize digital information transmission. The basic functions of digital include storage, calculation, operation, etc. Its performance directly depends on the number of transistors per unit area and is therefore very dependent on the process.

Classified by application

Data center-level chips: Mainly used in cloud computing data centers: including CPU, GPU, memory, storage controller, solid-state drive, etc., which mainly require high performance, high stability, and high reliability.

Consumer chips: Currently the most widely used chips with the highest market share, used in computers, mobile phones and other products.

Industrial chips: Industrial products have been exposed to harsh environments of extremely high/low temperature, high humidity, strong salt spray and electromagnetic radiation for a long time. The use environment is harsh. Therefore, industrial chips must have stability, high reliability and high safety, and have long service life.

Automotive grade chips: mainly because they have strict requirements on the temperature environment and can be used in a wider temperature range.

Military chips: Semiconductor chips related to national defense and military industries, such as satellite communications, guidance, and precision navigation.

Classified by technology

1971,10μm process

1974,6μm process

1977,3μm process

1982,1.5μm process

1984,ASML found。

1985,1μm process

1989,0.8μm process

1994,0.6μm process

1995,0.35μm process

1997:250nm process

1999:180nm process

2001:130nm process

In 2003, ASML cooperated with TSMC to launch an immersion lithography machine, and ASML has surpassed other manufacturers in one fell swoop. The 157nm light source dry lithography machines promoted by Japan’s Nikon and Japan’s Canon, both lithography giants, were gradually abandoned by the market, and the two companies turned from prosperity to decline.

2004:90nm process

2006:65nm process

2008:45nm process

2010:32nm process

2011:22nm process

In 2013, ASML launched the first EUV mass-produced product, and NXE:3300 was officially shipped, further strengthening the monopoly position in the industry.

2014:14nm process

2017:10nm process

2018:7nm process

2020:5nm process

2022:3nm process

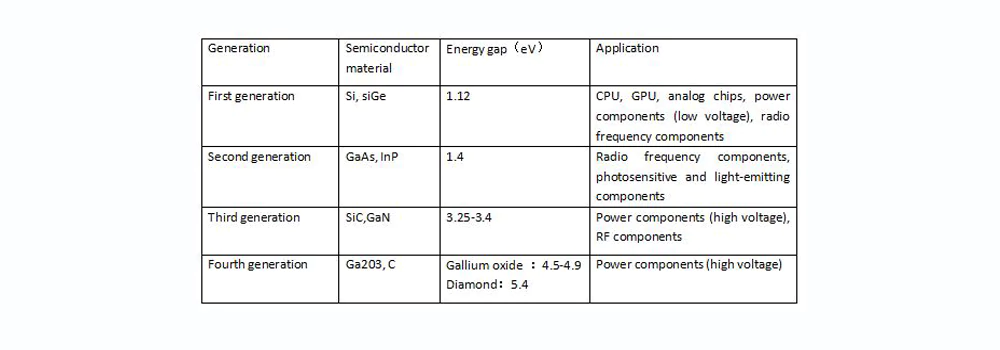

Classified by semiconductor material

Classified by industrial chain

According to the order of the integrated circuit industry, semiconductor chips include five major processes: silicon wafer production, IC design, wafer manufacturing, packaging and testing.

Semiconductor chip manufacturing can be divided into front-end process and back-end process. Front-end processes include photolithography, etching, thin film deposition, ion implantation, cleaning, chemical mechanical polishing, measurement and other processes. The back-end processes include thinning, dicing, chip mounting, bonding and other packaging processes as well as terminal testing.