The outbreak of new energy vehicles has accelerated, and power components have ushered in new opportunities for growth.

Under the background of the current global economic recession and the downward cycle of the entire semiconductor industry, automotive semiconductors seem to have become a contrarian development industry.

At the same time, with the development trend of the new four modernizations such as vehicle electrification, intelligence, networking, and sharing, as well as the continuous booming market of new energy vehicle production and sales, automotive electronics is ushering in opportunities for structural change.

New energy vehicles (hybrid vehicles or pure electric vehicles, etc.) have significantly higher semiconductor content than traditional vehicles.

Compared with fuel vehicles, new energy vehicles no longer use gasoline engines, fuel tanks or transmissions, and the “three electric systems” – batteries, motors, and electronic control systems replace them.

New core components such as DC-DC modules, motor control systems, battery management systems, and high-voltage circuits have been added, in which power devices such as MOSFETs and IGBTs play a very key role.

Application of power semiconductors in new energy vehicles

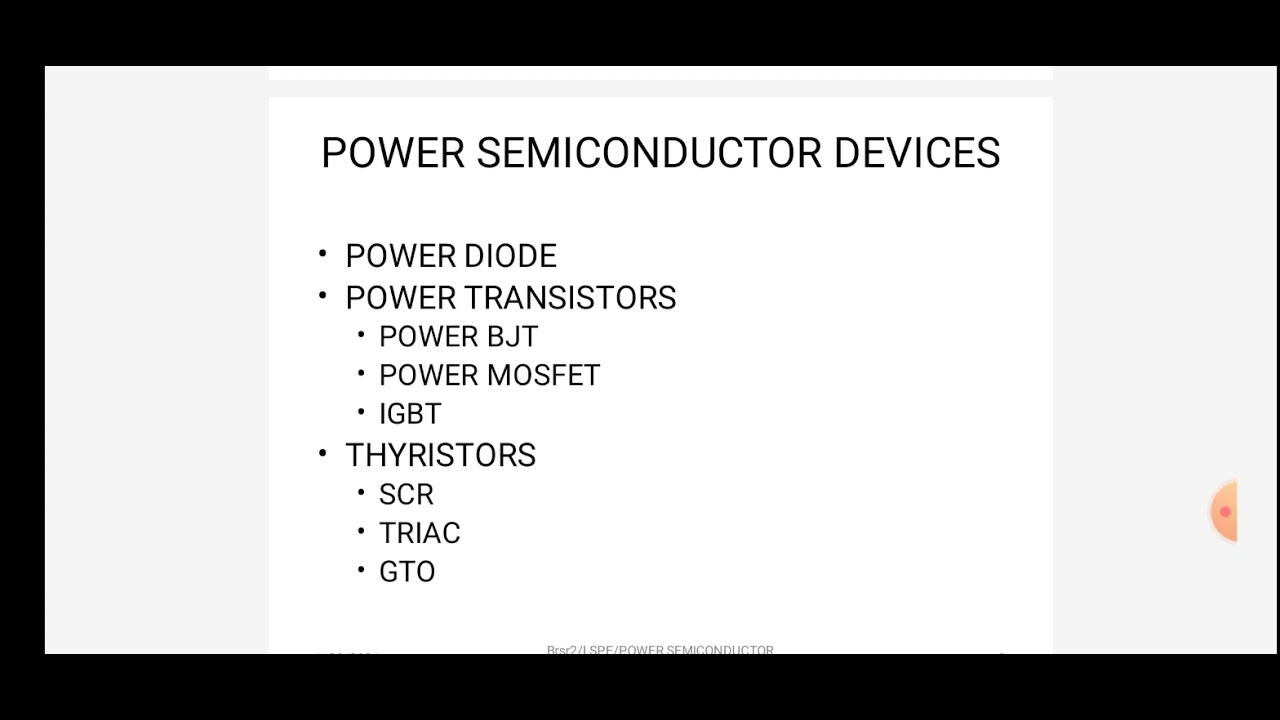

Power semiconductors are the core of power conversion and circuit control in electronic devices, mainly used to change voltage and frequency in electronic devices, DC AC conversion, etc., and the change of the automotive industry will drive the growth of power components consumption.

According to the report, the value of power semiconductor components in new energy vehicles is more than 5 times that of traditional fuel vehicles. In addition, power components will also be used in electric vehicle charging stations and bring further growth in the market size.

According to statistics, the automotive-grade power semiconductor market has the largest growth, with revenue of about $6.1 billion in 2020 and is expected to reach $26.5 billion by 2030, which will be the largest market in the entire automotive semiconductor market.

Power devices usher in new opportunities for growth

MOSFET

The full name of MOSFET is called metal-oxide semiconductor field effect transistor, which belongs to the basic device of power semiconductor, with small driving power, fast switching speed, high working frequency, strong thermal stability, widely used in high frequency and low voltage low power, play the role of amplification circuit or switching circuit.

MOSFETs can be divided into two types of “N-type” and “P-type” according to the polarity of their “channels”, usually called NMOSFET and PMOSFET, and different types of MOSFET withstand voltage performance and range.

In today’s emerging new energy electric vehicles, silicon-based MOSFETs are indispensable and are the core components in automotive electronics. It is predicted that in 2022, the automotive field will account for up to 22% of MOSFET terminal applications, 19% in PC computers and storage devices, and 14% in industry.

In fact, before entering the era of new energy vehicles, MOSFETs have been used in areas involving electric functions in fuel vehicles, such as auxiliary brakes, power steering and seat control systems.

With the start of vehicle electrification, the demand for MOSFETs has surged. New energy vehicles use electric braking to make medium and high voltage MOEFETS as important components of DC-DC, OBC and other power sources used in the vehicle power domain to complete the conversion and transmission of electric energy, and the consumption per vehicle has increased to more than 200.

In addition, with the development of automotive intelligence, ADAS, safety, infotainment and other functions require MOSFETs as the basic devices for power conversion to support digital, analog and other chips to complete the function realization, so that the amount of high-end vehicle MOSFETs can increase to more than 400.

According to statistics, by 2026, the global automotive-grade MOSFET market is expected to be $3 billion, with a compound annual growth rate of 12.25%.

IGBT

As mentioned above, MOSFETs are widely used in both traditional fuel vehicles and new energy vehicles, which makes the market increment of automotive-grade MOSFETs not as obvious as IGBTs under the new four changes of automobiles.

IGBT, insulated gate bipolar transistor, is a composite power semiconductor device composed of BJT (bipolar transistor) and MOSFET, which has the advantages of high withstand voltage of BJT and high input impedance of MOSFET, known as the CPU of new energy vehicles in the industry, is the core of new energy vehicles, which directly controls the conversion of DC and AC power of the drive system, and determines the core data such as the maximum output power and torque of new energy vehicles.

At the heart of electric vehicles lies the high-voltage (200-450V DC) battery and its associated charging system. The main motor drive of pure electric vehicles generally requires the driving power of the power device to be 20-150kW, and the average power is about 70kW. Due to the high driving power, voltage and high energy consumption sensitivity, electric vehicle factories often use IGBT modules with low on-voltage drop and high operating voltage.

It can be seen that compared with silicon-based MOSFETs, IGBTs are more suitable for high-voltage operation, and the two complement each other.

In the electric drive system, IGBT is used in the inverter module to convert the direct current of the battery into alternating current to drive the motor. In the power supply system, IGBT is used in various AC-DC and DC-DC converters to realize the functions of charging the battery and completing the power conversion of the required voltage level.

In addition, the car battery swap station also needs an IGBT inverter power module to reverse the direct current into alternating current, and then convert it into different specifications of current voltage through the transformer coupling and distillation unit to realize the charging of electric vehicles.

In terms of market competition pattern, IGBT is currently dominated by European and Japanese manufacturers, and the top five manufacturers account for more than 60% of the market. According to statistics, Infineon currently has a market share of 32.7%, which is an absolute giant in the IGBT field.

From the perspective of value, IGBT accounts for about 37% of the cost of the electronic control system of new energy vehicles, and is one of the most core electronic devices in the electronic control system, and the higher the degree of electrification, the higher the proportion of IGBT in the car. It is estimated that by 2025, the global IGBT scale of new energy vehicles will be close to 4 billion US dollars, with a five-year CAGR of 39.4%, and the market space is huge.

From the current market point of view, due to the outbreak of the demand side of new energy vehicles and the mismatch of the expansion cycle of the supply side, the entire automotive IGBT is currently in a state of serious supply and demand.

Silicon-based devices and SiC power components

For a long time, automotive-grade power semiconductors mainly use silicon-based materials, but due to their own performance limits, the power density of silicon-based components is difficult to further increase, and the loss of silicon-based materials under high switching frequency and high voltage is greatly increased.

In this regard, the third generation of wide bandgap semiconductor materials represented by SiC (silicon carbide) and GaN (gallium nitride) has gradually emerged, which is suitable for high power, high frequency and harsh working environment, and solves the drawbacks of silicon-based components.

Among them, SiC, as a new generation of wide bandgap semiconductor materials, has the characteristics of large band gap, high breakdown electric field, high saturation electron drift speed, high thermal conductivity, and high radiation resistance, and is suitable for manufacturing high temperature, high pressure, high frequency, and high power components. Therefore, the industry has high hopes for the application of SiC power components in electric vehicles.

In terms of application scenarios, SiC power devices are mainly used in the fields of electric drive, OBC and DC/DC conversion, which can significantly reduce the size, weight and cost of power electronic systems and improve power density. Miniature and lightweight SiC devices can also reduce energy consumption due to the weight of the vehicle itself.

Taking the application in the main drive inverter as an example, what are the advantages of silicon carbide MOSFETs over Si-IGBTs?

– Compared with silicon-based IGBT, silicon carbide MOSFETs have higher power conversion efficiency, and the cruising range of electric vehicles can be extended by 5-10%, that is, battery capacity can be reduced and battery costs can be reduced under the same cruising range;

– The high-frequency characteristics of silicon carbide MOSFETs can make the inverter coil and capacitor smaller, the size of the electric drive can be greatly reduced, and the reduction of audible noise can reduce the iron loss of the motor;

– Silicon carbide MOSFETs can withstand higher voltages, and the current intensity can be reduced by increasing the voltage when the motor power is the same, so that the beam line is lightweight and saves installation space.

Conclusion

At present, with the transformation and accelerated outbreak of the new energy vehicle industry, the structure of automotive-grade semiconductor devices is changing rapidly. Among them, as the largest incremental product, power devices account for more than 80% of the incremental value of semiconductors per vehicle, and are ushering in a stage of rapid development.

In this process, automotive power devices are also undergoing changes from silicon-based MOSFETs to IGBTs and SiC devices, leading the update and iteration of automotive power devices with material upgrades, thereby promoting new energy vehicles to make new breakthroughs and making the future full of infinite possibilities.