Electrolytic capacitor is a kind of capacitor, its positive electrode (aluminum or tantalum) is a metal foil, and the oxide film close to the metal with the positive electrode is a dielectric; Its negative electrode is composed of conductive materials, electrolytes and other materials, because the electrolyte is the main part of the negative electrode, the electrolytic capacitor is named.In this article, we will understand the role of electrolytic capacitors, judgment methods, and considerations.

The role of the electrolytic capacitor

Filtering

In the power supply circuit, the rectifier circuit turns AC into pulsating DC, and after the rectifier circuit, a larger capacity electrolytic capacitor is connected, and its charge-discharge characteristics (energy storage) are used to make the pulsating DC voltage after rectification become a relatively stable DC voltage.

In practice, in order to prevent the power supply voltage of each part of the PCB circuit from changing due to load changes, electrolytic capacitors are generally connected to the output end of the power supply and the power input end of the load.

Since large-capacity electrolytic capacitors generally have a certain inductance, they cannot effectively filter out high-frequency and pulse interference signals, so a capacitor with a capacity of 0.001–0.lpF is connected in parallel at both ends to filter out high-frequency and pulse interference.

Coupling

In the process of transmission and amplification of low-frequency signals, in order to prevent the static working points of the front and rear circuits from affecting each other, capacitors are often used to couple. In order to prevent excessive loss of low-frequency components in the signal, electrolytic capacitors with larger capacity are generally used.

The judgment method of electrolytic capacitor

Common faults of electrolytic capacitors are reduced capacity, capacity disappearance, breakdown short circuit and leakage. Among them, the capacity change is caused by the gradual drying up of the electrolyte inside the electrolytic capacitor during use or placement, and the breakdown and leakage are generally caused by the applied voltage being too high or its own poor quality.

To judge the quality of electrolytic capacitors, the multimeter is generally used for measurement.

The specific methods are:

The capacitor is short-circuited to discharge the two pins, and the black probe of the multimeter is connected to the positive terminal of the electrolytic capacitor. The red probe is connected to the negative pole (for the pointer multimeter, the probe is intermodulated when measured with a digital multimeter), and the pointer should first swing in the direction of small resistance under normal circumstances, and then gradually return to infinity.

The greater the swing amplitude of the pointer or the slower the return speed, the greater the capacitor, and vice versa, the smaller the capacitor. If the pointer stays in the middle and no longer changes, it means that this capacitor leaks; If the resistance indication value is small or zero, it indicates that this capacitor has broken through a short circuit.

Because the battery voltage used in the multimeter is generally very low, it is more accurate when measuring the capacitance of low withstand voltage; When the withstand voltage of the capacitor is high, although the measurement is normal, leakage or breakdown may occur after adding high voltage.

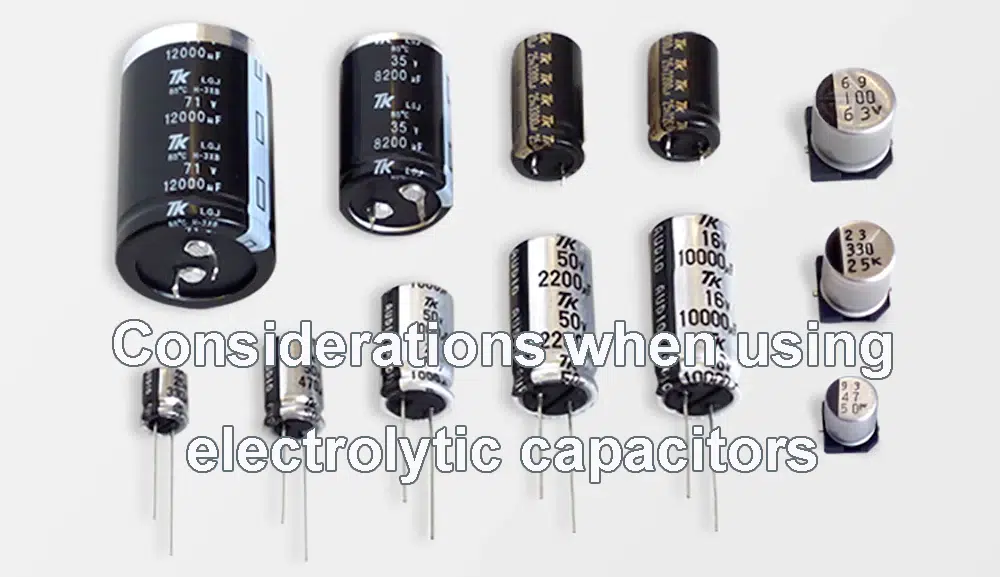

Considerations when using electrolytic capacitors

1.Due to the positive and negative polarities of electrolytic capacitors, they cannot be connected upside down when used in the circuit. In the power supply circuit, when the positive voltage is output, the positive terminal of the electrolytic capacitor is connected to the power supply output, and the negative terminal is grounded. When the negative voltage is output, the negative pole is connected to the output and the positive pole is grounded.

When the polarity of the filter capacitor in the power supply circuit is reversed, the filtering effect of the capacitor is greatly reduced, which on the one hand causes the output voltage of the power supply to fluctuate, and on the other hand, the electrolytic capacitor equivalent to a resistor heats up due to reverse energization. When the reverse voltage exceeds a certain value, the reverse leakage resistance of the capacitor will become very small, so that the capacitor can burst and damage due to overheating shortly after the power is applied.

2. The voltage applied to both ends of the electrolytic capacitor cannot exceed its allowable working voltage, and a certain margin should be left according to the specific situation when designing the actual circuit. When designing the filter capacitor of the regulated power supply, if the rectification voltage of the transformer secondary is 22V when the AC power supply voltage is 220~, the electrolytic capacitor with a withstand voltage of 25V is generally selected for PCB prototype. However, if the AC supply voltage fluctuates greatly and is likely to rise above 250V, it is best to choose an electrolytic capacitor with a withstand voltage of 30V or more.

3. The electrolytic capacitor should not be close to the high-power heating component in the circuit to prevent the electrolyte from drying up faster due to heating.

4. For the filtering of signals with positive and negative polarity, the method of connecting two electrolytic capacitors in series with the same polarity can be adopted as a non-polar capacitor.

5. The capacitor shell and auxiliary lead terminal must be completely isolated from the positive and negative polarity and the circuit board.